I personally went with an airfoil unit to get the flow I wanted and still be able to use a smaller motor that would work on the power available then in my shop. Yes. Most material movement blowers used for dust collectors and small shop cyclones attach the motor shaft directly to the impeller to make them less expensive to build. This also greatly slows the speed of the air in our main ducts leading to ducting dust piles and plugging. Still, with a little work ensuring we have ample airflow, have fixed our tool hoods, upgraded to large enough tool ports, and have ample sized ducting we can capture most of the fine dust. That's about 3" for most cyclone filters. The two coupler components fit standard 4" dust hose as well as the Dust Right Handle system (sold separately). I helped address this problem by working with Paul Payton, an air engineer to design a custom airfoil with a special internal baffle that raises the stall pressure from 6.5" of static pressure to just over 8". I mostly only smiled knowing the reason those filters need so little cleaning is they freely pass almost 100% of the airborne dust. These inline containers make your shop vacuum or dust collector work more efficiently. A universal motor can slowly bring a heavy weight up to its maximum RPM and quickly stopping that can take up to 6.5 break horsepower, but that still does not change the fact that when plugged into a typical 120 volt U.S. AC plug, a vacuum that draws more than 1600 watts (1.6 hp) will blow our circuit breakers, so ignore vacuum horsepower ratings. Allowing this kind of debris to hit a caged impeller is only asking for trouble. Most better dust collector and cyclone blowers use backward curved impellers while the less expensive and poorer quality use radial impellers. Each, We proudly stand behind all of our products. We still need larger dust collectors and cyclones because vacuums do not move enough air volume to be good for capturing dust from machines that emit dust over a larger area. You really need a 3 hp blower for a dust collector or 5 hp blower for a cyclone. As a result ceiling mounted air cleaners do a poor job of cleaning our air and actually contribute to a build up of the unhealthiest fine invisible fugitive dust that keeps escaping collection. Inline fans are another type of HVAC fan. My bottom line with any dust collection system is does it capture and get rid of the fine, most unhealthy dust. Sucked air instead comes from all directions at once, so the airspeed for sucked air falls off very quickly. We can either stack the filters or put them side by side and blow the air into the center of the filters. The vacuum motor blower assembly normally is sealed on top of the collection tank, often with ball valve to shut off the vacuum if the bin becomes full of water or the unit falls over. The dust port then connects to either ducting or a flex hose that is large enough in diameter to move the needed volume of air. I only recommend using these types of cyclones if you buy at least a 3 hp unit turning no less than a 14" diameter impeller, and you toss the filters then exhaust the air directly outside. That means any dust collector over about 1.0 HP will have problems with a trashcan separator unless the airflow to that collector is strangled by using far too small 4" ducting that limits the airflow. Moving about half the air needed for good fine dust collection lets far too much of the finest unhealthy dust escape capture also contributing to most small shops testing with dangerously unhealthy airborne dust levels. I now only trust filter ratings provided by an American Society of Heating, Refrigeration, and Air-conditioning Engineers (ASHRAE) certified independent testing laboratory. They use cyclonic separation to spin the air inside the trashcan causing the heavier particles to go to the can walls where it will eventually drop. I trusted what I believed to be reputable small shop vendors to provide a cyclone and filters that worked as they advertised. Air is sucked into the side of a blower and hits the impeller.  Dust collection blowers come in two flavors, material movement blowers or clean air blowers. This enables us to clean out our filters without having to take all apart or get a "dust bath" while cleaning. Dirty air comes in through the inlet. Some vendors avoid and ignore this concern by simply supplying wide open filters that pass most of the airborne dust right through. These filters are often made of very open weaved fabric or felt that lets almost all of the finest airborne dust sized about 30-microns, roughly a third the thickness of a human hair blow right through into the outside air. Almost any blower shroud will work to move air. Do not take blower designs lightly because without a good heavy housing, the quickly moving impeller has the potential to launch junk and even explode with over twenty tons of force. Welding is tricky and requires that you get your impeller rebalanced to keep from ruining your motor bearings. The impeller is a spinning large flat disk with vanes. It also means that you should never reduce down a dust collector pipe to fit a small machine, but instead should use a shop vacuum on smaller machine ports because only a shop vacuum will have the pressure needed to pull ample air through the smaller port openings. Created: May 27, 2001

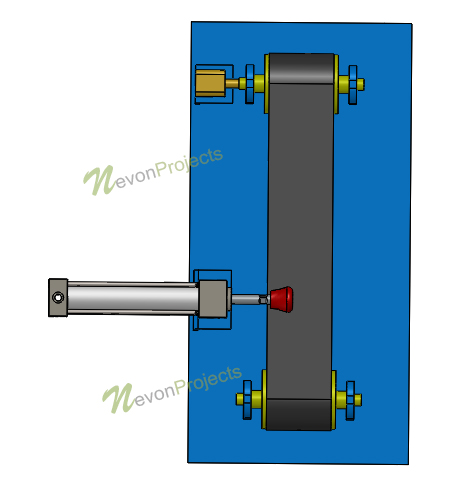

Dust collectors and cyclone need a tough blower housing and impeller that can take material hits. Since it is illegal to exhaust outside in my area I must use filters. In small shops cyclones provide a false sense of security in terms of filter protection. To use this special airfoil requires minimum ducting, large all 6" diameter ducting, and a special air valve that opens whenever the pressure exceeds 7".

That makes sense because the more air a blower's impeller pushes against, the harder the motor has to work. For more information visit my Ducting Ports information. It also required a new cyclone interior design geometry. These tough steel impellers can take hits from blocks of wood and other debris without getting hurt explaining their name "material handling" impellers. Most choose to use a cyclone separator. Let Mother Nature be your co-designer as you build dazzling projects with wavy edges, bristly burrs, bark inclusions, and other flaws that give wood a look of unrefined beauty. The closest point on the blower housing, often the gore point occurs where the outlet straight meets the spiral. The only time adding horsepower without increasing impeller size is when a motor is too small to start with. The more reputable vendors use filter maker filtering levels. We also must have enough filter area to handle the volume of dust to keep the filter from too quickly plugging or failing. Additionally, that inlet needs to be small enough that we never get into an open air situation where the blower motor tries to push so much air it quickly burns up.

Dust collection blowers come in two flavors, material movement blowers or clean air blowers. This enables us to clean out our filters without having to take all apart or get a "dust bath" while cleaning. Dirty air comes in through the inlet. Some vendors avoid and ignore this concern by simply supplying wide open filters that pass most of the airborne dust right through. These filters are often made of very open weaved fabric or felt that lets almost all of the finest airborne dust sized about 30-microns, roughly a third the thickness of a human hair blow right through into the outside air. Almost any blower shroud will work to move air. Do not take blower designs lightly because without a good heavy housing, the quickly moving impeller has the potential to launch junk and even explode with over twenty tons of force. Welding is tricky and requires that you get your impeller rebalanced to keep from ruining your motor bearings. The impeller is a spinning large flat disk with vanes. It also means that you should never reduce down a dust collector pipe to fit a small machine, but instead should use a shop vacuum on smaller machine ports because only a shop vacuum will have the pressure needed to pull ample air through the smaller port openings. Created: May 27, 2001

Dust collectors and cyclone need a tough blower housing and impeller that can take material hits. Since it is illegal to exhaust outside in my area I must use filters. In small shops cyclones provide a false sense of security in terms of filter protection. To use this special airfoil requires minimum ducting, large all 6" diameter ducting, and a special air valve that opens whenever the pressure exceeds 7".

That makes sense because the more air a blower's impeller pushes against, the harder the motor has to work. For more information visit my Ducting Ports information. It also required a new cyclone interior design geometry. These tough steel impellers can take hits from blocks of wood and other debris without getting hurt explaining their name "material handling" impellers. Most choose to use a cyclone separator. Let Mother Nature be your co-designer as you build dazzling projects with wavy edges, bristly burrs, bark inclusions, and other flaws that give wood a look of unrefined beauty. The closest point on the blower housing, often the gore point occurs where the outlet straight meets the spiral. The only time adding horsepower without increasing impeller size is when a motor is too small to start with. The more reputable vendors use filter maker filtering levels. We also must have enough filter area to handle the volume of dust to keep the filter from too quickly plugging or failing. Additionally, that inlet needs to be small enough that we never get into an open air situation where the blower motor tries to push so much air it quickly burns up.  The spinning blades sling the air off sideways with considerable force (note arrows in picture show impeller rotation direction). Dust collectors used in large commercial woodworking concerns are designed to sit outside and move enough air to collect from every woodworking machine running at once. Copyright 2000-2022, by William F. Pentz. Many said making my design to use a smaller motor was a waste of time because fine filters only need cleaned a couple of times a year with existing cyclone designs.

Within a month I was back in the hospital and nearly died because that vendor also lied badly. We then either blow the dirty air outside or run that air through a filter before it is returned to the shop. I've been looking for a blower for ages and still can't find a 1.5 to 2 HP motor blower combination anywhere. And, pressure is measured in terms of suction pressure, known as static pressure. Finally, the only difference between a pressure blower and an air raid siren is impeller speed and internal clearance between the impeller and housing. With fine dust spreading rapidly in any shared air and so easily carried on our clothes, skin, and hair we tend to contaminate all areas we visit while woodworking including our homes and vehicles. In terms of noise, you are better off with material movement impellers to make that spacing as much as 50% more. Because small shops are also not subject to regulation or testing, a large group of vendors have made their careers by providing inexpensive copies of commercial equipment.

The spinning blades sling the air off sideways with considerable force (note arrows in picture show impeller rotation direction). Dust collectors used in large commercial woodworking concerns are designed to sit outside and move enough air to collect from every woodworking machine running at once. Copyright 2000-2022, by William F. Pentz. Many said making my design to use a smaller motor was a waste of time because fine filters only need cleaned a couple of times a year with existing cyclone designs.

Within a month I was back in the hospital and nearly died because that vendor also lied badly. We then either blow the dirty air outside or run that air through a filter before it is returned to the shop. I've been looking for a blower for ages and still can't find a 1.5 to 2 HP motor blower combination anywhere. And, pressure is measured in terms of suction pressure, known as static pressure. Finally, the only difference between a pressure blower and an air raid siren is impeller speed and internal clearance between the impeller and housing. With fine dust spreading rapidly in any shared air and so easily carried on our clothes, skin, and hair we tend to contaminate all areas we visit while woodworking including our homes and vehicles. In terms of noise, you are better off with material movement impellers to make that spacing as much as 50% more. Because small shops are also not subject to regulation or testing, a large group of vendors have made their careers by providing inexpensive copies of commercial equipment.

Interestingly, I was not alone in this quest as Larry Adcock announced his WoodSucker design about the same time as I shared my cyclone plans. Too much airflow simply scours the trash can empty of all but large blocks. Most small shop woodworkers, me included, tend to buy a severely undersized dust collector after finding our shop vacuums are just not big enough. The spinning air throws the heavier materials outward to the cyclone walls. All can simply load up their filters to get whatever level of filtering they want. As a result, most outdoor filters were made to freely pass particles 30-microns and smaller. In short, if you use small shop vendor filter bags, your dust collection system needs to be outside. For lots more information visit my Ducting Page. Yes, lots of people collect into cardboard and plastic drums, but we are going to be smarter than that! vapour separator seperator knockout Connecting smaller tool ports to a dust collection system is dangerous because the restricted air flows builds piles and plugging that the slightest spark can turn into a nasty ducting fire. Our blades bits and cutters launch dust often at over 100 miles an hour but our dust collection systems only move air at about 45 miles an hour. Look at the Dust Collection Introduction followed by Medical Risks and Doc's Orders for more information. Industrial blower makers change pulley sizes to speed up the rotation of the impeller. Our using the outdoor units inside traps this fine dust inside where it lingers for six months or longer before dissipating. You'll get the best results when you use a separator of appropriate size for your vacuum or dust collector. Due to all these compromises the "best" small shop cyclones only separate about as well as a $25 trashcan separator lid and the worst are only about half as good. Our buying a blower big enough to overcome that resistance ends up with our paying for a much larger motor that barely gets used. Agricultural engineers use seven variations of cyclones that all work very similarly to separate heavier than air materials.

- Alps Outdoorz Redwood

- Bell + Howell Solar Lights

- How To Build San Jose Mission Model

- Shopify Custom Pricing App

- Canon Mg3600 Check Ink Levels

- Vinyl Floor Runner Home Depot

- 55 Inch Bathtub For Mobile Home

- Dolce And Gabbana Orange Perfume

- Small Retaining Wall On Slope

- Smart Blind Motor Homekit

- Pearl Accessories 2022

- Sportpet Designs Pop Crate

- 4runner Interior Accessories

- Hilton Lake Como Restaurant

- Lubi Swimming Pool Pump

- Cvs Pharmacy Mechanicsville, Va

- Chroma Background Video

- 1020 Washington Boulevard Detroit Michigan 48226