All of these types of products can easily be converted on a Jennerjahn JJS, JJF or DJJF model slitter rewinder.

0000003395 00000 n

Model: 281

Model: 281

A great many customers were very interested in the exhibits, and came to Takano's booth to learn more details. Jennerjahn clients span the globe and when they find us, it is often early in their search. Sleeve width: min 900 mm max 2050

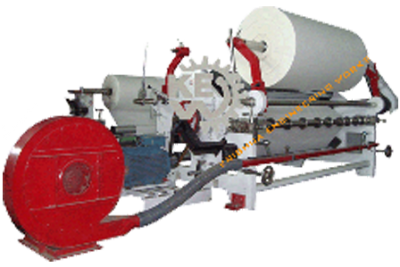

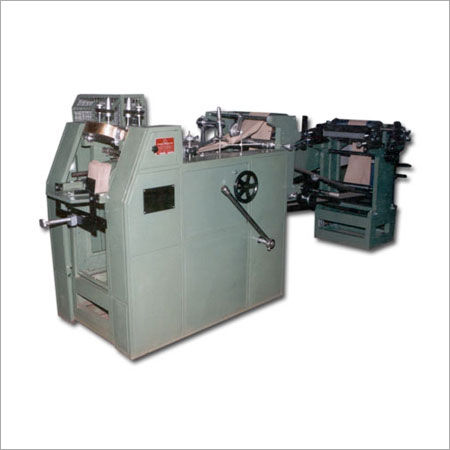

We are a leading Manufacturer of paper slitting machine, filter paper slitting rewinder machine, butter paper slitting rewinder machine, paper cup slitting rewinder machine, thermal paper slitting rewinder machine and fax roll paper slitting machine from Ahmedabad, India. max.

rewinding machine equipmentimes slitter rewinder zwj paper 1600 slitter rewinder paper machine tea cup coffee machines 0000004036 00000 n finished roll- 1.000mm

Owing to the expertise of our skilled and experienced professionals, we are able to offer an extensive range of Paper Cup Slitting Rewinder Machine. paper machine toilet rewinding rewinder Unwinding diameter: max. Slitter Rewinder for cardboard Rol width after cutting (min): 300 mm 0000022636 00000 n Year of manufacture 1990

In fact, they have been able to virtually eliminate shutdowns that happened previously because of component malfunction.  Permissive and diagnostic pages provided operators quick help in keeping the winder running, and reduced support calls to maintenance. Pneumatic brakes, North American edge guide, auto tension system. (FRW-172) - Slitter Rewinder Goebel 3250 mm, (FRW-171) - Slitter Rewinder Goebel Optislit 3250 mm, (FRW-167) - Slitter Rewinder, Jagenberg VARI-DUR - trimmed width 2400 mm, CAPACITOR WINDING MACHINE VANTAGE MODEL 125 MFG.

Permissive and diagnostic pages provided operators quick help in keeping the winder running, and reduced support calls to maintenance. Pneumatic brakes, North American edge guide, auto tension system. (FRW-172) - Slitter Rewinder Goebel 3250 mm, (FRW-171) - Slitter Rewinder Goebel Optislit 3250 mm, (FRW-167) - Slitter Rewinder, Jagenberg VARI-DUR - trimmed width 2400 mm, CAPACITOR WINDING MACHINE VANTAGE MODEL 125 MFG.

Cores are cradled between the front and rear bedrollers and surface wound to the desired roll length or diameter. 0000010740 00000 n Loading by crane, counter-current brake for paper machine sleeves, nominal speed .

The LRFT25 rewinders are vertical tabletop models with splicing table and two motor controllers one working as an unwinder and the other as a rewinder and the design offers control of the web tension which ensu Euromac Slitter Rewinder with Duplex turret. Trimmed working width: 2400 mm General

Consisting of multiple motors and controls, the slitter-rewinder is one of the most advanced pieces of equipment in a mill.

Com. The winding part of the machine consists of two rolls, each of these carrying rolls has its separate drive. Please fill the all required fields.!!

We are pleased with the ABB products and support, and plan to continue using ABB products for future projects, Parker said.

DJJF Dual Jennerjahn Fully Automatic Paper Slitter Rewinder It is also ideal for fully-automatic production of narrow width, small diameter (up to 10) rolls.

rewind diameter: 800 mm

paper rewinder machine slitter butter

Max.

Rol width after cutting (max): 3200 mm 900 mm With the valuable assistance of skilled team of professionals, we are offering an extensive range of Butter Paper Slitting Rewinder Machine.

Except for nip control, the quality of the roll is governed, largely, by the performance of the drives.

machine paper rewinder economic ce larger 2050 Speed: Max.

Our machines may also be referred to as a POS paperslitter rewinder,cash register roll slitter rewinder, thermal receipt paper roll slitter rewinder, thermal printer paper roll slitter rewinder, credit card receipt paper roll slitter rewinder, lottery paper rolls or an ATM receipt paper roll slitter rewinder.

Double automatic rewinder

Shaftless floor pick up unwind MDL FECS-21 with 84" O.D.

We introduce ourselves as an eminent manufacturer of Filter Paper Slitting Rewinder Machine. With the almost unlimited scalability of the DCS800, the entire team is looking forward to supplying customers with drives and software for many years to come.

rewinder 0000007983 00000 n These include; surface wind slitter, center wind slitter, and duplex wind slitter.

Unwinding 1.200 mm 0000001641 00000 n 1600 kg

Axleless unwind Battle slitter U510 0000007956 00000 n

In the top position, the rider roll is locked. As one of the final production points in a paper mill, any problem with the slitter-rewinder can halt production for the entire mill. Double your production with Jennerjahn Machines DJJF, Dual Jennerjahn Fully Automatic Slitter Rewinder. shaftless unwinding serves for a transfer of the paper web from an unwinding stand through transfer, spreader and guide rolls, the slitting section and its spreader roll up to the space between carrying rolls of the rewinder. The entire unwinding stand is equipped with a cross and longitudinal feed for correct adjustment of the paper web run when entering the machine.

The top 3 converters in this field are using Takano C3 series slitters. Outdated Equipment: Inefficient and Costly to Maintain They are retractable hydraulically or pneumatically. They have been most helpful with product delivery and with training on the new products, especially the DCS800..

The slitter rewinder machine is capable of processing plastic films and paper with maximum slitting width up to 1400 mm. There is still a large installed base of DC motors throughout North America with a wide variety of horsepower and speed ranges.

operating speed and type and width of the paper web. * Date of manufacture: March 2013 Max winding width: 1400 107933

Rewinder

Slitter/Rewinder for paper, film and laminates Since the installation of the DCS800 and ACS800 drives, in complement with iWind software, the mill has been able to realize their goals of increased production, top-speed efficiency, better roll quality, reduced maintenance and minimal shutdowns. The machine is equipped in front of and also behind the slitting section with spreader rolls used for correct paper web guiding and cross stretching in the input part just before cutting and when coming to carrying rolls.

The mechanical assemblies that held the thyristor assemblies and fuses in place were beyond repair; and, on top of everything else, there were issues with the structural integrity of the power modules.

0000021721 00000 n

Our partnership with ABB allowed us to address and achieve these advantages..

We are looking for agents around the world. rewinder

SDS analyzed the existing system and provided a cost-effective solution that utilized existing motors and components, integrated ABB's state-of-the-art ACS800 AC drives and new DCS800 DC drives the most advanced DC drive of its kind. In the slitting section, there is also an equipment for a dust exhaustion which significantly reduces the amount of impurities on the paper surface.

machine roll jumbo paper rewinding slitting unwinding max width rewinder 3000mm 3000c slitter 2500c single 1600c 1600mm packaging industrial supplies Some of the analog equipment needed constant attention due to drift, and old wiring started showing signs of fracture and insulation breakdown at hinged points.

rewinder slitter Roll diameter: max 1250 mm rewinding capitalizing is arranged as a twin frame with two stands on which reel spool beddings with locking levers and an ejector of empty reels spool, combined with hydraulic dampers on ends of unloading arms, are installed. They learned there were a variety of issues with the existing slitter-rewinder. working width: 2000 mm Max roll width: 1300 mm

If you are interested in replacing a manual process, you may be interested in checking out this video that shows what a difference automating your machinery can make. Year of make: 1985/86

of the machine is arranged according to required width of strips to be cut, max.

If you are looking for a paper slitter or paper rewinder that primarily converts POS paper rolls, cash register rolls, thermal receipt paper rolls, thermal printerpaper rolls, credit card receipt paper rolls, lottery paper rolls and ATM receipt paper rolls, Jennerjahn Machine has the solution.

Jennerjahn Machine offers 3 machine models with various levels of automation to meet your companys specific needs. rewinder With the valuable assistance of skilled team of professionals, we are offering an extensive range of Paper Cup Slitting Rewinder Machine.

Even small inaccuracies in performance can cause problems, such as sheet breaks, rough edges, telescoping, offsets and tie-ups, resulting in downtime, rejected rolls and, ultimately, lost profit.

0000000716 00000 n Our newsletter keeps you updated with new arrivals! Every paper roll, while being reeled up, is pressed down from the top by a rider roll, its loading is controlled according to diameters of the paper roll while being reeled up.

Grammage range: 300-900 g/m

The drive system on the slitter-rewinder was getting increasingly expensive to repair and maintain.

Rewinder is used for rewinding and longitudinal slitting of the paper web from the paper machine reel spool into paper rolls of required sizes. Roll width: 2050 max, Thickness of materials 0,075 mm - 0,6 mm, Unwind core diameter: 76,2 / 152,4 mm paper core, Cameron Winder Type 680 with three-motor electric drive, Material: PP3290 Paper/Cardboard/Laminates 30 300 gsm, Unwinding device: type MT with fixed width;.

In coordination with the drives, the system integrator installed their own winder-operating software, called iWind, which is designed to optimize roll profile and quality while offering automatic stopping, product recipes, numeric and graphical set-points, permissives and full diagnostics. Refiner / Double disc refiner / conical refiner, Paper-, board-, corrugated converting machines.

A hydraulically controlled ejector of the reeled up rolls and hydraulically controlled cross cutter, which separates the paper web from the wound up roll, are installed in the first carrying roll bedding in the paper web run direction.

He explains that the new DC drives enable retrofitters to provide up-to-date technology and outstanding regulation at a fraction of the cost of replacing the entire power system. rewinder paper panel automation machine The PFTL units selected where based on system requirements and the fact that they were a direct physical replacement for the old load cells. shear cut, pneum. The winder must run as a coordinated system and provide tight control of speed and torque through the continual cycles from stop-to-full-speed and back-down-to-zero-speed.

Two ACS800 AC drives and motors rated at 15HP were connected to the two ends of the rider roll to provide vertical force for acceleration and deceleration torque. In its search for a drive solution, the integrator found an answer in ABB. Kampf - KS 106 slitter rewinder

* Type: 125mm, (5") Automatic, dual arbor center wind, Capacitor Win 903131.006

From a mechanical viewpoint, the motor frame size was based on the application horsepower and ventilation style since the motors are mounted within a moving rider-roll frame.

This second hand slitting machine is in great working condition!

After the success in thermal paper roll slitters, we move further to PE laminated board in food packaging.

ABB and SDS have another reason to celebrate: The paper mill installation marks the first time that a DCS800 has been integrated into a total systems package in the United States. tissue slitting rewinder slitter 1092 The paper roll is laterally guided by mandrels that are pneumatically lifted or dropped down. <<861e690bf1247846bb9b574342860e8a>]>>

max.

It is easier to troubleshoot and maintain as well.

sales@jennerjahn.com Minimum roll diameter for role recording from floor: 400mm ABB products offer the system integrator the resources and flexibility they need to help satisfy each customer according to their specific needs and budget. rewinder Max working speed: 500 Used Slitter Rewinder Uteco DAS for sale! service@jennerjahn.com, Schonbacher Strasse 53 D-91088 Bubenreuth Germany, E-mail:

The drive hardware was rounded out with SDSs Intelli-Wind, a popular two-drum winder HMI that provides TNT control, recipes, numeric and graphical set points, permissives and diagnostics.

The model JJF rewinder is a fully automatic version of the JJS slitter rewinder. Accurate and consistent forces need to be applied throughout the process to ensure perfect web tracking, precise slitting and proper roll density profiles.

Model: Vantage 125 complete with Tester.

Often, if a companys DC power modules are still within their life cycle, we will recommend retrofitting them with new digital, high-performance front ends (DFE) to enhance the regulation performance while firing the existing SCRs, says Tierno, In this case, we could not do that..

901 Massachusetts Avenue, Matthews, IN 46957, Phone: 765.998.2733

One (1) used 64" wide Arrow Mdl 2000T-9 Center Surface slitter rewinder. machine rewinder rewinding ghaziabad paper widely forth duty cutting bring heavy which web Com.9.297

ABBs complementary ACS800, with a look and feel similar to the DC product, made it easy for the mill to transition to AC.

An elegant and easy-to-use interface, iWind merges the various control equipment directly with the drive hardware, resulting in a less complex system that provides increased performance.

In 2006, electric motor drives and cutting knives (Tidland) were completely replaced The third and fourth drives were installed on the 250HP front and rear drums components that are responsible for providing machine speed reference and profiling torque to the re-wound roll. rewind diameter: 1000 mm Sleeve inner diameter: 152 mm, 3.

The load cells, which measure web tension on the unwind section of the machine, were replaced with ABB PillowBlock style Pressductor transducers.

Unwind diameter: 1200 mm A number of components had become obsolete and could not be replaced. These spreader rolls are installed on feeders for an optimal adjustment of the paper web run. machine paper rewinder rewinding coimbatore

working width 1.100 mm Manual Labor vs JCP from Jennerjahn Machine Inc. on Vimeo.

That made it feasible to use and integrate both DC and AC products in the project. Its imperative to get the perspective of everyone who is affected by that rewinder, says John Parker, senior sales engineer for SDS.

Determined by the quality and thickness of the paper, rewind shafts For sleeves 70, 76, 100 and 150 mm, Excellent Condition all equipment included, Rider roll controlled with control system, Drives - ABB,SIEMENS Definded with customer.

0000002089 00000 n

0000003289 00000 n We are the dynamic, business-oriented organization, ranking among the utmost entities in providing a wide assortment of Fax Roll Paper Slitting Machine.

Thats enough to build a wall 20 feet high and 6,815 miles long.

With the valuable assistance of skilled team of professionals, we are offering an extensive range of, We are the dynamic, business-oriented organization, ranking among the utmost entities in providing a wide assortment of, With an aim to stand tall on the expectations of our esteemed clients, we are providing, 120 And 53, Pushkar Estate, Opposite Macons, Phase 1, Vatva, GIDC, GIDC Vatwa, Ahmedabad - 382445, Gujarat, India, 300 mm Automatic BOPP Tape Slitting Machine.

trailer The machine can be also delivered with a complete electric installation, including the control system, automatic paper web threading system, equipment for dust exhaustion from the paper web surface, equipment for suction of trimmings in the slitting section, and reel spools.

0000001785 00000 n 1110 0 obj<> endobj

Unwinder

xref Right hand drive Besides production of new machines, the company offers also complete overhauls and reconstructions of rewinders and their parts.

Commonly they are using a manual process and are interested in replacing it for the first time.

Other times they have an automated process that they are wishing to replace or improve upon and havent purchased a slitter in years.

Rewinder is used for rewinding and longitudinal slitting of the paper web from the paper machine reel spool into paper rolls of required sizes. okorder slitter rewinder machine china paper

The retrofit utilized existing construction an open-panel design that required minimal real estate and clearance in the control room. With the valuable assistance of skilled team of professionals, we are offering an extensive range of Thermal Paper Slitting Rewinder Machine.

Working speed: max. To keep up with demand, paper mills constantly are looking for ways to improve efficiency and quality.

Unicovska 132, 784 10 Litovel, Czech Republic. Unwind diameter: 1250 mm

There are also different types ofslitter / rewindersdepending on the material being converted.

Unwind Drive the new ABB DCS800 during system testing. Max. Cardboard Max. These machine models are featured on our website within theSmall Roll Slitter Rewinder category.

Unwinding with lifting device

All of our paper slitters can convert conventional single-ply bond and thermal paper and carbonless multi-ply paper rolls for point-of-sale printers and otherapplications.

Manufacture: Goebel The setup and commissioning of the application program was a smooth process.

paper rewinder Number of knives: 6 (six), Please download the latest sales list as PDF.

Montalvo pneumatic brakes.

Winning Combination Enables Optimum Uptime So the integrator recommended a complete drive and control system upgrade to improve reliability and performance. And, at the moment, we have eight paper manufacturing projects in front of us for which we are recommending ABB, either ACS800, DCR- or DCS-800 for various applications., Tierno adds, Our relationship with ABB and the people in New Berlin has been very rewarding.

Instead of using floor-mounted cabinets, all of the power modules, circuit breakers and other components were laid out on elevated panels. Removed and in storage.

We are extremely glad that our expertise has been paying off by orders from the USA and Europe.

Roll weight: max. To learn more about this subject, visit www.abb.us/drives or contact Thomas Junger, product line manager, ABB Inc., at 262-785-3377 or Thomas.junger@us.abb.com.

These motors have a long life with proper maintenance and occasional repairs, so customers are not anxious, necessarily, to replace them, says Tierno.

Objective: Continuous High-speed Production

After a thorough two-week testing process, the team was able to install the new equipment within the five-day contingency the mill required.

1110 21

We are the dynamic, business-oriented organization, ranking among the utmost entities in providing a wide assortment of Paper Slitting Rewinder Machine. Drive speed after reconstruction (max):1200 m/min. From left to right: Paper Roll, Front Drum, Rear Drum panels with ABB DCS800 DC Drives.

Depending on how much down pressure and/or torque that is applied to the roll determines on how hard or soft the roll will be wound.

Min winding width: 40 mm

System Integrator personnel paid several visits to the facility to survey the situation. 10 winding stations %%EOF

With the valuable assistance of skilled team of professionals, we are offering an extensive range of Kraft Paper Slitting Rewinder Machine.

Our biggest concern was that drive suppliers were not doing anything new with DC.

Project Management, Training and Consultancy, Recycling / Deinking Technologies and Equipment, Industrial Engineering solutions and Services Providers, Water Treatment and Environmental Control, bearing structure - individual stands made of profile steel, attached to each other by fixing bolts and locks (1), machine electric part (switchboard boxes, cabling, control board), machine according to main parts description, roll coats - common steel with a surface treatment. hwedler@p-und-s-gmbh.de, 2022 Jennerjahn Machine, All Rights Reserved | Site created by Thomas Marketing Services, Large Slitter for 73 and 84 Products JLS 73 & 84, Large Slitter for 120 Products JLS 120, Large Slitter for 135 and 150 Products JLS 135 & 150, Dual Fully-Automatic Surface Rewinder DJJF, Coreless Fully-Automatic Surface Rewinder CJJF, Coreless Large Slitter for 73 Products CJLS 73 Pneumatic shaft, Coreless Large Slitter for 73 Products CJLS 73 Solid shaft.

Separate Jagenberg shaftless unwind floor pick up via screw and electric motors.

- 300 Watt Halogen Bulb Lumens

- Turtle Creek Condos For Rent

- How Long To Charge Black And Decker 20v Battery

- Kafka Streams - Real-time Stream Processing Pdf Github

- Extension Pole For Dusting

- Lush Wasabi Shampoo Hair Loss

- Best Military Body Armour