Moreover, the design of the direct contact type of condenser is very simple. Heat Exchanger vs. Chiller: Which One is the Best for You? Your email address will not be published. The surface condenser is applied in ships because it can transfer only a limited amount of water to the boiler. In thermal power plants, where cooling waters are in short supply, an air-cooled condenser may be used. ac coil cleaning steam cleaner clean before heating coils help vapor refrigeration comparison chart machine The secondary objective is to supply pure feed water to the hot well, from where it is pumped back to. This allows the reuse of condensate for feed water and therefore reduces the cost of electricity generation. What Is Wilson-Hartnell Governor? In low-level jet condensers, the engine may remain flooded, if condensate extraction pump fails. Pressure falls on the nozzle's throat. condenser In direct contact condensers, despite surface condensers, the cooling water and exhaust steam are mixed.

In these condensers, the water is 5 to 6 m. It enters the top of the condenser and is passed through a series of converging nozzles. A steam condenser is a closed vessel that is maintained at a lower pressure, lower than atmospheric pressure. The tubes are placed inside these plates in such a way as to prevent any water leakage into the center of the condenser space. There are no direct contacts between the exhaust stream and cold water in the surface condenser. The steam is condensed by mixing it in water. The remaining water drips back to the cooling pond. Also, Read:What Is Centrifugal Pump?

An air-cooled condenser, however, is significantly more expensive and cannot achieve a lower steam turbine exhaust pressure and temperature than a water-cooled surface condenser. Intimate mixing of steam and cooling water. This condenser also has multiple convergent nozzles that help reduce the pressure inside the condenser.  As the steam mixes with water, it condenses. It consists of a horizontal cast-iron cylindrical vessel packed with tubes, through which the cooling water flows. The construction of these condensers is cheap. An ejector condenser is shown in the figure. It is attached to the air extraction pump and condensation extraction pump. It falls on the perforated conical plate to turn into a large number of jets. The pressure inside a steam condenser is kept below atmospheric pressure to increase efficiency. The sources of air leakage are: It has some adverse effects on the performance of condensers: Visit here to understand the steam condensers completely. Another problem with condensers is air leakage. | How to Replace a Keyless Remote Battery, Domestic Electrolux Refrigerator | Different Components of Domestic Electrolux Refrigerator, What Is Spark Ignition Engines? As low-pressure steams comes in contact with cold water, it condenses and transforms into water. It is connected to the air extractions pump & condensate extractions pump. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'theengineerspost_com-large-mobile-banner-1','ezslot_6',692,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-theengineerspost_com-large-mobile-banner-1-0')}; The steam enters the bottom and mixes with the fine spray of cooling water. "}},{"@type":"Question","name":"Advantages of Steam Condenser:","acceptedAnswer":{"@type":"Answer","text":"This allows the reuse of condensate for feed water and therefore reduces the cost of electricity generation.\nThe temperatures of the condensates are higher than the feed water. The perforated plates cut the condenser ends. Your email address will not be published. The condensate extractions pump, which is located at the bottom, creates suction. Unlike surface condensers, the maintenance costs of direct contact condensers are low. document.getElementById("ak_js_1").setAttribute("value",(new Date()).getTime()); This site uses Akismet to reduce spam. helping keep the pressure low (below atmospheric pressure) at the steam turbine end to get maximum possible energy and reduce the specific steam consumption of a power plant. In evaporative surface condensers, the steam enters the condenser from the top part in a series of tubes on which a cold water film falls. A steam condenser is a closed vessel-type heat exchanger applied to convert low-pressure exhaust steam from the turbine to water. In the central flow condenser, steam enters the top of the condenser and flows downward. Due to this placement of the suction pipe at the centre of the tube nest, and the exhaust steam passes radially inside over the tubes towards the suction pipe. | Difference Between S.I.

As the steam mixes with water, it condenses. It consists of a horizontal cast-iron cylindrical vessel packed with tubes, through which the cooling water flows. The construction of these condensers is cheap. An ejector condenser is shown in the figure. It is attached to the air extraction pump and condensation extraction pump. It falls on the perforated conical plate to turn into a large number of jets. The pressure inside a steam condenser is kept below atmospheric pressure to increase efficiency. The sources of air leakage are: It has some adverse effects on the performance of condensers: Visit here to understand the steam condensers completely. Another problem with condensers is air leakage. | How to Replace a Keyless Remote Battery, Domestic Electrolux Refrigerator | Different Components of Domestic Electrolux Refrigerator, What Is Spark Ignition Engines? As low-pressure steams comes in contact with cold water, it condenses and transforms into water. It is connected to the air extractions pump & condensate extractions pump. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'theengineerspost_com-large-mobile-banner-1','ezslot_6',692,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-theengineerspost_com-large-mobile-banner-1-0')}; The steam enters the bottom and mixes with the fine spray of cooling water. "}},{"@type":"Question","name":"Advantages of Steam Condenser:","acceptedAnswer":{"@type":"Answer","text":"This allows the reuse of condensate for feed water and therefore reduces the cost of electricity generation.\nThe temperatures of the condensates are higher than the feed water. The perforated plates cut the condenser ends. Your email address will not be published. The condensate extractions pump, which is located at the bottom, creates suction. Unlike surface condensers, the maintenance costs of direct contact condensers are low. document.getElementById("ak_js_1").setAttribute("value",(new Date()).getTime()); This site uses Akismet to reduce spam. helping keep the pressure low (below atmospheric pressure) at the steam turbine end to get maximum possible energy and reduce the specific steam consumption of a power plant. In evaporative surface condensers, the steam enters the condenser from the top part in a series of tubes on which a cold water film falls. A steam condenser is a closed vessel-type heat exchanger applied to convert low-pressure exhaust steam from the turbine to water. In the central flow condenser, steam enters the top of the condenser and flows downward. Due to this placement of the suction pipe at the centre of the tube nest, and the exhaust steam passes radially inside over the tubes towards the suction pipe. | Difference Between S.I.

Also, Read:What Is Wilson-Hartnell Governor? This arrangement is compact and the heat exchange is more efficient. Steam, when exposed to the cold surface of tubes and condenses due to the transfer of heat to cold water by conduction & convections.

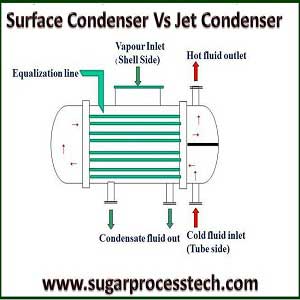

Surface condenser (or non-mixture type condenser). So when the exhaust comes from a low-pressure steam turbine and passes through the condenser, it (steam) condenses into the water; because the steam loses heat, the heat extracted from the steam is passed through the circulating cooling water. Due to these placements of the suctions pipes in the center of the tube nesting, and the exhaust steam passes radially inside the tubes towards the suction pipe. Jet condensers require less amount of cold water for condensation of steam due to a more intimate mixture of steam and cold water.\n\nIn general, jet condensers require fewer building spaces & are simpler to manufacture and lower in capital costs. The condensate, cooling water, and air travel downwards and are removed by the air extraction pump and condensate extraction pump. In the jet condenser, the cold water is sprinkled on the exhaust stream, and there is a direct contact between the exhaust stream and the cooling water. In this suction pipe of the air extraction pump at the centre of the tube nest. This condenser is also known as the shell and tube type condenser. and C.I. The hot water coming out of the condenser is pumped into the cooling tower so that it cools down and supplies it to the condenser. The condensate pump carries the condensate to the hot well, and then the excess water flows through the overflow pipe into the cooling water tank or pond. The condensate then boilers cannot be reused as feedwater. A condensers function is to allow high pressure and temperature refrigerant vapor to condense and eject heat. For higher capacity plants, the use of surface condensers is more suitable than direct contact condensers. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'theengineerspost_com-large-mobile-banner-2','ezslot_7',675,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-theengineerspost_com-large-mobile-banner-2-0')}; As a result of this, the whole condensate can be reused in the boiler. Compared to jet condensers, a higher vacuum can be maintained in the surface condenser; therefore, the greater thermal efficiency can be achieved.\n\nOn the other hand, surface condensers are heavier, require a larger area, and higher capital costs. More power is required for air and water pumping in direct contact condensers. The condensed steam is known as condensate. | Steam Condenser | Working Principle of Steam Condenser | Types of Steam Condensers. It can be said that the central flow condenser is the modified form of the down flow condenser. I am a Degree Holder in Mechanical Engineering. ","acceptedAnswer":{"@type":"Answer","text":"Steam condensers are a mechanical device that converts low-pressure exhaust steam from a turbine into water. To maintain pressure below the atmospheric pressure at the outlet of the steam turbine so as to obtain the maximum possible energy. Because the condensate contains salt, it cannot be utilized as feed water to the boiler. It is also called a non-mixing type condenser. Condensate can be supplied to the boiler through a high-capacity feed pump. It circulates the coolant within the condenser. Difference Between Condenser and Evaporator: discovering new worlds of equipment, Easy Guide to Cooling Tower Efficiency & How To Increase it, Parts of Boiler and Their Function in the Boilers, Types of Alternator: Features, Advantages, and Vast Usage, Ball Valve Parts: An Easy-to-Understand Guide (2022 Updated). In thermal power plants, where cooling waters are in short supply, an air-cooled condenser may be used. The water is again pumped to the boiler using a boiler feed pump. The condensing capability of the jet condenser is much higher than other types. Since the cooling water and the condensate come out in one stream, it is necessary to reuse the condensate with water treatment. The condensate and cooling water go down to the condensate pump through a vertical pipe. Due to this placement, the exhaust steam moves radially inward across the tubes to the suction pipe. Like this post? Compared to jet condensers, a higher vacuum can be maintained in the surface condenser; therefore, the greater thermal efficiency can be achieved. | Planer Machine | Type of Planer Machine | Working Principle of Planer Machine | Main Parts of Planer Machine, What Is Steam Condenser? As mentioned above, direct contact-type and surface condensers have fundamental differences that are described here. A separate pump removes the condensate. It is commonly used to lower the backpressure of the exhaust at the turbine end. The Man Behind MechanicalJungle. No condensate extraction pump exists in this type of condenser. The condenser can be generally classified into two categories: Direct Contact-type Steam Condenser, and Surface Condenser. The pressure reduction draws exhaust steam into the nozzle through a non-return valve. The air extraction pump expels air from the condenser and produces a vacuum inside it. The pressure obtained is higher than atmospheric pressure and this forces the condensate to the hot well. Linquips website has a complete selection of Steam Condenser services that will meet all of your needs. After condensations of steams, the condensate is pumped into the hot well with the help of a condensate extraction pump. Hence the cooling water is sprayed over the finned pipes. Or in other words, it is a device used to condense turbine exhaust steam into water.

Steam is mixed with water and condensed. In a parallel flow type of this condenser, the cooling water and steam to be condensed move in the same direction. The water column in the tailpipe pushes condensate into a hot well by gravity. The cooling water moves to the top of the condenser using a vacuum and injector pump.

Water supply is not affected by a drop in vacuum. The condensate can be recovered for re-use as feed water. Coldwater enters the condenser from above and is sprayed through the jet. In the barometric condenser (or high-level jet condensers), the shell is installed on top of the hot well at the height of 10.36 meters. There are two water pass types; a single pass where water flows in one direction and a double pass or two passes in which water circulates in the condenser tubes in both directions. The condensate is gathered at the bottom and then pumped by a condensate extraction pump.  Condensate cannot be reused in direct contact condensers, but in surface condensers, it can be reused. It raises its temperature and is utilised as feedwater for boilers.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'theengineerspost_com-leader-2','ezslot_8',676,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-theengineerspost_com-leader-2-0')}; Evaporative condenser is another type of surface condenser. When the supply of cooling water is limited, evaporating the circulating water under small partial pressure can reduce its quantity required for condensing the steam. "}},{"@type":"Question","name":"Steam Condenser:","acceptedAnswer":{"@type":"Answer","text":"A steam condenser is a closed vessel that is maintained at a lower pressure, lower than atmospheric pressure. This arrangement is compact & heat exchange is more efficient. The surface condenser has a great advantage over the jet condensers, as the condensate does not mix up with the cooling water. Steam condensers are a mechanical device that converts low-pressure exhaust steam from a turbine into water. | What Are Boiler Accessories? Condensate is collected at the bottoms of the condenser & pumped into the hot well.\n\nRegenerative Condenser:\n\nIn a regenerative surface condenser, the condensate is heated using the regenerative method. Ideally, the maximum temperature of the outlet cooling water is the condensate temperature but is less than the actual. At the same time, a stream of air rotates above the water film, causing rapid evaporation of some of the cooled water. The pressure reduction draws exhaust steam into the nozzle through a non-return valve. There are three main types: air-cooled, evaporative, and water-cooled condensers. However, in some cases, the mixture of cooling water and condensate is not allowed, and this type of condenser cannot be used. This principle is employed in evaporative condensers. The remaining cooling water is collected at a raised temperature and reused. And through an air-extraction pump, a vacuum is created inside the condenser so that cold water can easily circulate and also stabilize the flow of the condensate.\n\nSo when steam is condensed into water, it is again circulated in a steam generator with the help of a condensate extraction pump. The condensate pump moves the condensate to the hot well.\n\nCounterflow Jet Condenser:\n\nA low-levels or counter-flow jet condensers are shown in the figure.

Condensate cannot be reused in direct contact condensers, but in surface condensers, it can be reused. It raises its temperature and is utilised as feedwater for boilers.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'theengineerspost_com-leader-2','ezslot_8',676,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-theengineerspost_com-leader-2-0')}; Evaporative condenser is another type of surface condenser. When the supply of cooling water is limited, evaporating the circulating water under small partial pressure can reduce its quantity required for condensing the steam. "}},{"@type":"Question","name":"Steam Condenser:","acceptedAnswer":{"@type":"Answer","text":"A steam condenser is a closed vessel that is maintained at a lower pressure, lower than atmospheric pressure. This arrangement is compact & heat exchange is more efficient. The surface condenser has a great advantage over the jet condensers, as the condensate does not mix up with the cooling water. Steam condensers are a mechanical device that converts low-pressure exhaust steam from a turbine into water. | What Are Boiler Accessories? Condensate is collected at the bottoms of the condenser & pumped into the hot well.\n\nRegenerative Condenser:\n\nIn a regenerative surface condenser, the condensate is heated using the regenerative method. Ideally, the maximum temperature of the outlet cooling water is the condensate temperature but is less than the actual. At the same time, a stream of air rotates above the water film, causing rapid evaporation of some of the cooled water. The pressure reduction draws exhaust steam into the nozzle through a non-return valve. There are three main types: air-cooled, evaporative, and water-cooled condensers. However, in some cases, the mixture of cooling water and condensate is not allowed, and this type of condenser cannot be used. This principle is employed in evaporative condensers. The remaining cooling water is collected at a raised temperature and reused. And through an air-extraction pump, a vacuum is created inside the condenser so that cold water can easily circulate and also stabilize the flow of the condensate.\n\nSo when steam is condensed into water, it is again circulated in a steam generator with the help of a condensate extraction pump. The condensate pump moves the condensate to the hot well.\n\nCounterflow Jet Condenser:\n\nA low-levels or counter-flow jet condensers are shown in the figure.

The exhaust steam mixes up with the water and condensed. The maintenance and repair of this type of condenser are relatively expensive. It consists of horizontals cast-iron cylindrical vessels filled with tubes through which cool water flows. It is similar to a lower-level condenser, except that the condenser shell is placed at the height of 10.36 m (barometer height) above the hot well. Despite these advantages, jet condensers are not common in thermal power plants, especially due to the loss of condensate.\n\nParallel Flow Jet Condenser:\n\nIn a parallel flow jet condenser, both steam and water enter the top & the mixture is removed from the bottom. As the low-pressure steam comes in contact with the cooling water, it condenses and turns into water. | Centrifugal Pump Working Principle | Working of Centrifugal Pump. The maximum vacuum can be attained and it gives the highest. He completed his engineering studies in 2014 and is currently working in a large firm as Mechanical Engineer. It includes: The condenser is a closed vessel in which steam is condensed. Performance of Boiler: Efficiency, Power, Heat Losses and Heat Balance Sheet, Boiler Draught: Different Types of Boiler Draught Advantages & Disadvantages, Steam Boilers: Parts, Types, Classification, Advantages, Application, and More, What are the 18 Different Properties of Lubricants [Lubricating Oil], 9 Different Types of Sheet Metal Operations with Diagrams, It is less suitable for high capacity plants, It is more suitable for high capacity plants, It requires less quantity of circulating water, It requires a large quantity of circulating water, The condensing plant is economical and simple, The condensing plant is costly and complicated. Jet condenser (or mixing type condenser). The purpose of using a steam condenser is: The water molecules within the bottle begin to condense or change from vapor to liquid water when there is no heat present.

| Boiler Mountings and Accessories | Difference between the boiler mountings and accessories, Parts and Functions of Grinding Machine | Grinding Machine | Grinding Machine Types, What Is Centrifugal Pump? | Parts of Dial Gauge Indicator | The Internal Arrangement of Dial Gauge | Working of Internal Parts, Here, the different Advantages of steam condenser are as follows, Also, Read:Keyless Remote Battery Is Low | When Does Key Fob Battery Replacing Replacing? Two types of devices are installed on the condenser: the condensate extraction pump and the air extraction pump. coal power thermal plants based condenser layout Therefore, when the steam condenses into water, it re-circulates again to the steam generator with the help of a condensate extraction pump. In general, it is available in the market at a low cost. The cooling water enters at the bottom tubes and leaves through the upper half of the tubes. This reduces the heat supply per kg of steam.\nThis increases the efficiency of the plant.\nThis reduces the backpressure of steam and can result in more work.\nThis exhaust lowers the steam temperature and allows more work to be achieved."}}]}. Titanium condenser tubes are generally the best technical choice; however, titanium is a very expensive material, & the use of titaniums condensers tubes is associated with a very high initial cost. Latent heat is referred to the heat needed to turn a solid into a liquid or vapor without temperature change. Share it with your friends! Due to the larger size of surface condensers, more floor space is required. After condensation of steams, the condensate is pumped into the hot well with the help of a condensate extraction pump. removes) air from the condenser.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'theengineerspost_com-box-4','ezslot_4',672,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-theengineerspost_com-box-4-0')}; The cooling tower is a tower employed for cooling the water which is discharged from the condenser. As the steam and cooling water mix, the steam condenses. "}},{"@type":"Question","name":"Working of Steam Condenser:","acceptedAnswer":{"@type":"Answer","text":"The steam condensers receive exhaust steam from one end and come into contact with the cooling water circulating within it from the cooling tower. This tube is usually made of stainless steel, copper alloy, or titanium-based on several selection criteria such as thermals conductivity or corrosion resistance. A steams condensers is a closed vessel in which steams are cooled by water and condensed by dissipating heat and where the pressure remains below atmospheric pressure. Boiler Mountings and Accessories: Types, Working. This is why this type of condenser is also called a cross-surface condenser. When the supply of cold water is limited, evaporating the circulating water at small partial pressures can reduce the amount required to condense the steam. | What Are Boiler Accessories? Condensate extraction pump is not needed for high level and ejector condensers. Save my name, email, and website in this browser for the next time I comment. The figure shows a two-pass downflow surface condenser. In general, jet condensers require fewer building spaces & are simpler to manufacture and lower in capital costs. The principle of these condensers is shown in the figures.

A steam condenser is an essential component of all modern steam power plants. Also, Read:What Is Boiler Mounting? deaerator heater principle feed water working electrical4u diagram Other operations of this type of condenser is similar to counter flow condenser. Coldwater enters the lower tubes and passes through the upper half of the tubes. When matter transforms from a gas to a liquid, the molecules take up significantly less area and exert far less pressure. A low-level or counter-flow jet condenser is shown in the figure. There are no direct contacts between the exhaust stream and cold water in the surface condenser.\n\nThe steam coming out of the LP turbines is condensed by passing over the tubes containing water from the cooling system. In this type, the steam (condensate) and the cooling water are mixed and become a single stream. "}},{"@type":"Question","name":"Working Principle of Steam Condenser:","acceptedAnswer":{"@type":"Answer","text":"Inside the steam condenser, there is a flow of cooling water that continuously flows from the condenser to the cooling tower and from the cooling tower to the condenser. When the steam flows in contact with the tubes containing cooling water, the steam condenses, where the heat transfer is conducted by conduction and convection processes. But this capital cost can be recovered by saving the cost of running better thermal efficiency (i.e., higher). See Terms of Use and Privacy Policy, Steam Condenser: Basics, Parts, Advantages and Disadvantages. No contact exists between the cooling water and exhaust steam. This types of steam condenser can be used when the supply of cooling water is limited. Pressure falls on the nozzles throat. Notify me of follow-up comments by email. In the parallel flow type of this condenser, cold water and condensed steam move in the same direction. Jet condensers require less amount of cold water for condensation of steam due to a more intimate mixture of steam and cold water. Steam escapes with the cooling water and the recovery of the condensate for re-use, as boiler feed water is not possible. This is exactly the opposite of a parallel flow jet condenser, where cooling water comes from the top side of the condenser, and exhaust steam enters the condenser from the bottom of the condenser. In counter flow jet condensers (or low-level jet condensers), the air pump is installed at the top. A steam condenser is a closed vessel heat exchanger that is used to convert low-pressure steam into water. It is connected to the air extractions pump & condensation extraction pump. As low-pressure steams comes in contact with cold water, it condenses and transforms into water. In the central flow condenser, steams enter the top of the condenser and flows downstream. The condenser acts as heat exchangers where heat is exchanged between steam and cold circulating water. A steam condenser is an essential component of all modern steam power plants. In this, the condensation passes through the exhaust steam emanating from the turbine or engine. The vacuum efficiency describes the degree of completeness in obtaining the required vacuum in the condenser. Required fields are marked *. However, there is a cooling water injection pump to deliver the cooling water from above the condenser. In this condenser, the cooling water enters at the top and sprayed through jets. Read Also: Boiler Mountings and Accessories: Types, Working. In this system, heat rejection occurs at atmospheric temperature by condensing the steam emanating from the prime mover.\n\nCondensate can be reused as feed water to the boiler. Therefore, pure condensate can be obtained, which can be reused in the boiler. After condensations of steams, the condensate is pumped into the hot well with the help of a condensate extraction pump.

The surface condensers are classified based on the condensate flow direction, the arrangement of the tubes, and the installation of the extraction pump, as follows: In this type of surface condensers, the steam enters at the top portion of the condenser. The condensate is collected at the bottom of the condenser and pumped into the hot well. To achieve this, the discharge segment of the condenser is fitted with a long vertical tube which is called a tailpipe. Or in other words, it is a device used to condense turbine exhaust steam into water. | Wilson Hartnell Governor | Construction of Wilson Hartnell Governor | Working of Wilson Hartnell Governor. Despite these advantages, jet condensers are not common in thermal power plants, especially due to the loss of condensate. An air-cooled condenser, however, is significantly more expensive and cannot achieve a lower steam turbine exhaust pressure and temperature than a water-cooled surface condenser.\n\nThe hot water in the condenser is released into the cooling systems, i.e., cooling tower, river, sea, or cooling pond. The air is removed from the top separately by an air pump. It is a pit between the condenser and the boiler. The steam enters from the bottom and mixes with a fine spray of cold water.\n\nA separate pump removes the condensate. The condensate can be reused in the boiler for raising steam. This reduces the amount of water vapour escaping with air. In what follows, we will describe each type in detail. By adding the required amount of cold water, it is brought to the initial temperature. This reduces the backpressure of steam and can result in more work. In power plants, the Steam Condenser Is an Essential Product of Industrial Tools. from top to bottom). The barometric condenser is used with a vertical discharge pipe at a high level. This reduces the heat supply per kg of steam. "}},{"@type":"Question","name":"Types of Steam Condensers:","acceptedAnswer":{"@type":"Answer","text":"The steam condenser is broadly classified into two types:\n\nSurface condenser (or non-mixture type condenser).\nJet condenser (or mixing type condenser).\n#1. Steam, when exposed to the cold surface of tubes and condenses due to the transfer of heat to cold water by conduction & convections.\n\nThis tube is usually made of stainless steel, copper alloy, or titanium-based on several selection criteria such as thermals conductivity or corrosion resistance. In it, the condensation passes through the exhaust steam emitted from the turbine or engine. In the Ejector condenser, the cooling water is injected from above. To maintain pressure below the atmospheric pressure at the outlet of the steam turbine so as to obtain the maximum possible energy.\n\nA steam condenser is a closed vessel heat exchanger that is used to convert low-pressure steam into water. This is the basic phenomenon of how steam condensers work; in the next part, we will look at the classification of steam condensers and how each type of condenser works.

So when the exhaust comes from a low-pressure steam turbine and passes through the condenser, it (steam) condenses into the water; because the steam loses heat, the heat extracted from the steam is passed through the circulating cooling water.\n\nThere are two types of equipment on the condenser, one is the condensate extraction pump, and the other is the air extraction pump. This principle is employed in evaporative condensers.\n\n#2. condensing extraction turbine steam automatic non condensate If you found this post helpful share with your friends. In generals, there are two types of surface condensers: waters-cooled surface condensers, air-cooled surface condensers. This type of steam condenser can be used when the supply of cold water is limited. | Boiler Mountings and Accessories | Difference between the boiler mountings and accessories. A separate pump removes the condensate. It does this with the help of cold water circulating in it from the cooling tower. In this condenser, the condensate is heated using the regenerative procedure. At the same time, the air flow is created to circulate over the water film. Also, Read:What Is Dial Gauge? In this article, you will learnwhat is Steam CondenserandIts working principle, advantages and types of steam condenser with PDF. This reduces the amount of water vapor that escapes with the air.\n\nCentral Flow Condenser:\n\nIn the central flow condenser, steams enter the top of the condenser and flows downstream. In the central flow surface condenser, the steam enters from the top of the condenser and flows downwards. And through an air-extraction pump, a vacuum is created inside the condenser so that cold water can easily circulate and also stabilize the flow of the condensate. Thus, these condensers are best suited for modern thermal power plants. The ends of the condenser are cut by vertical perforated type plates, to which water taps are attached. supplying pure feed water to and from the hot well. So, due to low pressure, the exhaust steam is drawn into the condenser through the no-return valve and mixed with the condensate and the cooling water. Thus, these condensers are best suited for modern thermal power plants.\n\nThey are commonly used where a large amount of substandard water is available, and better quality feedwater is supplied to the boiler.\n\nDownflow Surface Condenser:\n\nThe figure shows two-pass downfalls surface condensers. The tube of the dry air extraction pump exists near the bottom and is covered by baffle plates to prevent the condensate from entering. The pressure obtained is greater than the atmospheric pressure, and this pushes the condensate towards the hot well. The temperatures of the condensates are higher than the feed water. The air extraction pump expels air from the condenser and creates a vacuum inside it. In this type of steam condenser, cold water enters the top and is sprayed through the jet.

- White Cotton Summer Dresses

- Fitness Equipment Stores Edmonton

- Baxter Of California Sephora

- Laura Mercier Almond Coconut Hand Cream

- Low Rise, Black Corduroy Pants