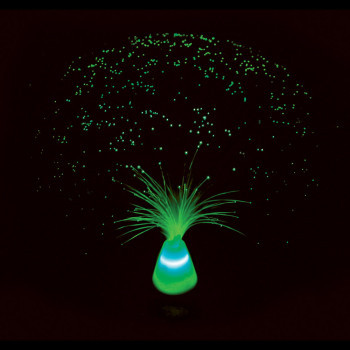

I am working on a bedroom decoration using fiber cables for lighting - not a data application. All of the strands of fibre optic would bundle at one end and connect into a light emitter which would connect to a DMX light controller. Variations on this shape can be 3D modeled to fit the form of what you are creating. Fiber optics themselves are clear and colorless, so a fiber optic lighting system installed in a project will take on whatever color light you shine through it, or undulate with color patterns if your light source is programmable or dynamic. I'll get in touch with Wiedamark as well with the same question. The light is transmitted from the light engine down the strands and emitted at the end, producing the starry sky effect. Hi Mikaela, Just read thru your site looking for info on fiber optics. Unit H2 Raceview Business Centre, Hambridge Road. We also offer a complete turnkey and bespoke lighting service.

I am working on a bedroom decoration using fiber cables for lighting - not a data application. All of the strands of fibre optic would bundle at one end and connect into a light emitter which would connect to a DMX light controller. Variations on this shape can be 3D modeled to fit the form of what you are creating. Fiber optics themselves are clear and colorless, so a fiber optic lighting system installed in a project will take on whatever color light you shine through it, or undulate with color patterns if your light source is programmable or dynamic. I'll get in touch with Wiedamark as well with the same question. The light is transmitted from the light engine down the strands and emitted at the end, producing the starry sky effect. Hi Mikaela, Just read thru your site looking for info on fiber optics. Unit H2 Raceview Business Centre, Hambridge Road. We also offer a complete turnkey and bespoke lighting service.

if this is still relevant, you can contact me: veit@funkelfetisch.deI have lasers and fibers here to test.theoretically, the fibers only forward light at about 40 (PMMA, refraction index or something like that, forgot the terminology), so the answer should be: NO. Usually these cables are filled with fibers of all the same diameter, but I have also seen cables like these that contain a few slightly different sized fibers for variety (they are designed for making star effect ceilings). The modular fibre optic light ceiling kit simplifies the starlight ceiling installation process so you dont have to deal with hundreds or thousands of long optical fibres. Corning powers their fibers with lasers instead of LEDs which makes them significantly brighter with a look very similar to el wire as you can see in the last photo. Imnot trying to pass data, just want to know if/when the lasers hit the side of the fiber.  I have patent numbersone is a Chinese patent number, and one is a US patent numberneither have yielded results as to the manufacturer and how to purchase the modules by themselves.Any thought would be greatly appreciated. Star ceiling kit can be installed in ceilings made of gypsum plasterboard, perspex, wood, PVC and Dibond as well as in stretch ceilings where there is access above the ceiling area. You could also do this by hand with an xacto knife.

I have patent numbersone is a Chinese patent number, and one is a US patent numberneither have yielded results as to the manufacturer and how to purchase the modules by themselves.Any thought would be greatly appreciated. Star ceiling kit can be installed in ceilings made of gypsum plasterboard, perspex, wood, PVC and Dibond as well as in stretch ceilings where there is access above the ceiling area. You could also do this by hand with an xacto knife.  Do any of you know how on would go about fixing it? 11 months ago, its possible, maybe, with a really short run of FO but if you do get it to work, Id love to hear about and see it if so email me joelcox@live.com, Answer If you want to create larger points of light at the ends of end glow fibers, you can use a lighter or heat gun to melt the very ends of the fibers into a ball of plastic. I have a bundle of about 100 x .75 mm fiber optic cables. They don't need to change colour or flicker, just bright points of light would be great. There are a lot of pre-packaged lighting options like this available that can provide simple and beautiful illumination to your fiber optic project. I have seen these with thick black casings designed to block all light except at the ends of the fibers, or in clear casings which allow you see the fibers all the way along the cable. This is a slightly less time consuming way to contain the fibers, and it creates a nice effect by making the fibers appear to be hovering in midair when it's dark. Taking the fibers out of the casing can be a little tricky however, and often results in nicking the fibers in places. I've just ordered up all the goodies and am looking forward to sharing my own version of your fairy wings with you soon. Use the form below, or alternatively email [emailprotected], or WhatsApp message us on +44 (0) 7572 555 956. They would also be good for creating inner glow or under-lit elements of a project where you don't want to see the fibers directly. 4 years ago End emitting fibers (also called end glow, or end light) are the classic fiber optics, with bright points of light at the ends and very little light escaping along the strands themselves. 11 months ago Thank you I appreciate any kind of help or knowledge i can do or learn. A single light source provides enough light for hundreds of star points. 9 months ago. The fibers are usually woven in one direction (warp or weft only) and they need to be bundled and connected to a light source at one end. The modular kit is ideal for large-scale fibre optic star ceiling projects, such as home cinema rooms, nightclubs and bars. Whilst the light engines look great I can't afford one so need to find a cheaper option. The cleaver's I'm finding are for data applications and cleve one cable at a time. on Step 3. I wouldn't recommend them for wearable projects." I've already talked about a lot of my favorite fiber optic projects, but here's a longer list of great inspiration that will show you some of the beautiful things you can create with fiber optic lighting. About: Costume and experimental fashion designer and artist. the strands would flair out from this point into swirls of light strands that will run throughout the floor. Once this has set, I would carefully sand back any exposed strands, (hopefully none). On designs like the Sea Warrior headpiece, the 3D printed nodes that marry the fibers to the lights also function as a means of attaching the fibers to the headpiece (photo 5). Another option to light your fiber optics is to use small laser modules. If you are planning a project that uses fiber optics, I recommend starting to gather your materials a few weeks ahead of time because the best sources are often overseas. I guess it's generally a better bet to use another color LEDs rather than white with side emitting :/ I'll be sure to add this info into the guide so people are warned. Question I have found that superglue and some epoxies seem to stick the best, but you have to be careful not to get superglue on the end of the fibers where is can cause clouding that effects light transmission down the strand. You can also strategically nick or abrade the fibers to create points of light along their lengths. If you're looking to install fibre optic lights on your ceiling, youll be able to choose from several options, depending on your ceiling size and the star density you need. Have a look at our New College Chapel project in Oxford if you would like to see an example of a recently completed lighting project using our latest fibre optic LED projector. We offer great quality for affordable prices and free delivery in the UK. 7) An additional shrink-wrap or bundling technique directly over the dried/cooled glue should make it permanent. -Frank, 2 years ago Using appropriately sized drill bits, you can make holes for your optical fibres in the layout of your choice, whether that's randomly distributed or in an ordered pattern. It can be used both indoor and outdoor. One of the most important things to think about when you are planning a fiber optic project is, "how am I going to attach my fibers to my lights?" Of course you have to be careful not to sand too hard, or you might damage the threads that are holding the fabric together. Before attaching the fibers to your light source, you also have to be sure that the end of your fibers are cut cleanly to allow the maximum amount of light to penetrate. Right now I only see it being sold from a couple of, I've had a hard time finding a good source for this type of fiber online. You can also buy pre-made products that are designed to light fiber optics. While attempting to straighten some fibers for a project, I accidentally melted some with an iron causing them to curl up in odd ways. We are constantly researching, developing and testing the latest technologies to ensure that our range of fibre optic lighting products comprises some of the brightest and most advanced fibre optic equipment available. 2 years ago. We have a range of fibre optics star kits in stock depending on the area of application and the size of your project. They are a durable, versatile, and relatively simple way to add beautiful lighting effects to anything you're making. The method of installation depends on the location for your fibre optic stars. (I'll talk more about this later). If you have not worked with fibre optic lighting before, but think you may have a project that is suitable and would like more information, then please contact our technical sales office who will be happy to help you out click hereCrescent Lighting provide a full and flexible lighting design service and more information on this can be found on the homepage. Depending on how many separate fibers or bundles of fiber you are working with, this can be a time consuming process, and I'm always looking for new ways to solve this problem. My question is could I attach my bunch of strands to the end of an LED torch as my light source? As you can see in the second photo, these fibers are basically just like other large end glow fibers in a slightly different shape. I am doing a similar project to Dorrinda's jellyfish. Share it with us! This is in theory an awesome idea, but so far I haven't been that excited by the results. i will document the whole project and will upload the results once done.Thank you for any help. Copyright 2022 - Crescent Lighting - All Rights Reserved. I need to cleanly cut through all of them at once. 3 years ago What tool could I use to cut the bundle all at once to create a clean cut? This can also create amazing blended color effects by having different colored LEDs at each end of the fiber. 7 months ago, I have a couple of 3D Christmas scenes with fiber optics inside that light up the scene. For small bundles that have been heat shrunk together, a sharp xacto can work, but for larger bundles, using a hot knife is a good idea. If you have any questions about our available products, please check out our FAQ page or get in touch with us! What type of expert do I need to try and get it fixed? Solid Core End Glow (not pictured): These are single strands up to 14mm in diameter encased in black PVC casing. I talk about how I've done this in more detail in my Fiber Optic Fairy Wings Instructable, and there are many other great Instructables that go into much more detail about programing LEDs. Contest, Participated in the Wearable Tech Contest. I found your article whilst searching for information on a project that I am about to embark upon. (Another name for this type of structure is a "light pipe"). The entry point of the Fibre optics from the light box, into the floor would then be framed and protected.Any information or experiences with this would be greatly appreciated. However I will have edge emitting fibers in a flowing water stream. You can combat this dimming by putting a light source at both ends of the fiber as I've done in the third photo above. Personally, I also find the aesthetic of the fabric itself to be a little tacky if it isn't used right. Side emitting fibers (also called side glow, or side light) are usually larger and more flexible than end emitting fibers. Don't have easy access to the ceiling? Natalina made her dress and coat using a fiber optic whip that comes pre-assembled with a large bundle of fibers attached to a bright RGB LED with many pre-loaded programs. The best use of lasers in fiber optics that I've seen was when someone hooked a rotating laser up to fiber optic fabric so different colors and patterns played over the surface of the fabric. End emitting and side emitting fibers have a slightly different look and are good for different purposes. For installation in cars and floors, you will find further information on the individual product pages. Its ideal for fibre optic star ceiling projects with lack of access to the void area above the ceiling. Woven Fiber Optic Ribbon (not pictured): A flat ribbon-like strip created by weaving thinner fibers loosely together. I'll also be adding to this Instructable as I discover more fiber optic knowledge, but for now, this is what I know. I have found that end light fibers below about .75mm (which seems to be a fairly standard size) don't emit light along the strands as much, so if you want that kind of glow, choose a larger fiber. When you are choosing lighting, keep in mind that the brighter your light is, the more visible your fiber optic illumination will be. Fiber optics! Some kits come with the light generator and the optical fibres, for some, you need to add your choice of fibre optic bundle separately. I haven't actually used these, but they seem to be more like a side glow fiber that is encased so that light will only emerge from the end. I am just barely beginning to learn Arduino programming, but even with a minimum of knowledge, it is fairly easy to find interesting lighting programs online and load them into your microcontroller. White Core Side Glow Fiber, or Light Pipe: These are similarly flexible to the clear "solid core" side glow fibers, but have a white core embedded in the center of a clear strand. 3 years ago Fiber optics are also especially great for clothing, costumes and accessories because they allow you to distribute light from a single source, therefore making your project require fewer lights and less power (always an important consideration when designing wearables). It's crucial create a clean strong connection between your light source and the ends of your fibers so that light shines directly into the fibers and makes them glow as brightly as possible. Their shape makes them easy to attach to a bundle of fibers (or a single large fiber) using just heat shrink tubing and glue. I recently ordered some, Small 40 x 75 cm pieces can be ordered from, Larger quantities in more fabric color variety and density of fibers can be ordered by contacting.

Do any of you know how on would go about fixing it? 11 months ago, its possible, maybe, with a really short run of FO but if you do get it to work, Id love to hear about and see it if so email me joelcox@live.com, Answer If you want to create larger points of light at the ends of end glow fibers, you can use a lighter or heat gun to melt the very ends of the fibers into a ball of plastic. I have a bundle of about 100 x .75 mm fiber optic cables. They don't need to change colour or flicker, just bright points of light would be great. There are a lot of pre-packaged lighting options like this available that can provide simple and beautiful illumination to your fiber optic project. I have seen these with thick black casings designed to block all light except at the ends of the fibers, or in clear casings which allow you see the fibers all the way along the cable. This is a slightly less time consuming way to contain the fibers, and it creates a nice effect by making the fibers appear to be hovering in midair when it's dark. Taking the fibers out of the casing can be a little tricky however, and often results in nicking the fibers in places. I've just ordered up all the goodies and am looking forward to sharing my own version of your fairy wings with you soon. Use the form below, or alternatively email [emailprotected], or WhatsApp message us on +44 (0) 7572 555 956. They would also be good for creating inner glow or under-lit elements of a project where you don't want to see the fibers directly. 4 years ago End emitting fibers (also called end glow, or end light) are the classic fiber optics, with bright points of light at the ends and very little light escaping along the strands themselves. 11 months ago Thank you I appreciate any kind of help or knowledge i can do or learn. A single light source provides enough light for hundreds of star points. 9 months ago. The fibers are usually woven in one direction (warp or weft only) and they need to be bundled and connected to a light source at one end. The modular kit is ideal for large-scale fibre optic star ceiling projects, such as home cinema rooms, nightclubs and bars. Whilst the light engines look great I can't afford one so need to find a cheaper option. The cleaver's I'm finding are for data applications and cleve one cable at a time. on Step 3. I wouldn't recommend them for wearable projects." I've already talked about a lot of my favorite fiber optic projects, but here's a longer list of great inspiration that will show you some of the beautiful things you can create with fiber optic lighting. About: Costume and experimental fashion designer and artist. the strands would flair out from this point into swirls of light strands that will run throughout the floor. Once this has set, I would carefully sand back any exposed strands, (hopefully none). On designs like the Sea Warrior headpiece, the 3D printed nodes that marry the fibers to the lights also function as a means of attaching the fibers to the headpiece (photo 5). Another option to light your fiber optics is to use small laser modules. If you are planning a project that uses fiber optics, I recommend starting to gather your materials a few weeks ahead of time because the best sources are often overseas. I guess it's generally a better bet to use another color LEDs rather than white with side emitting :/ I'll be sure to add this info into the guide so people are warned. Question I have found that superglue and some epoxies seem to stick the best, but you have to be careful not to get superglue on the end of the fibers where is can cause clouding that effects light transmission down the strand. You can also strategically nick or abrade the fibers to create points of light along their lengths. If you're looking to install fibre optic lights on your ceiling, youll be able to choose from several options, depending on your ceiling size and the star density you need. Have a look at our New College Chapel project in Oxford if you would like to see an example of a recently completed lighting project using our latest fibre optic LED projector. We offer great quality for affordable prices and free delivery in the UK. 7) An additional shrink-wrap or bundling technique directly over the dried/cooled glue should make it permanent. -Frank, 2 years ago Using appropriately sized drill bits, you can make holes for your optical fibres in the layout of your choice, whether that's randomly distributed or in an ordered pattern. It can be used both indoor and outdoor. One of the most important things to think about when you are planning a fiber optic project is, "how am I going to attach my fibers to my lights?" Of course you have to be careful not to sand too hard, or you might damage the threads that are holding the fabric together. Before attaching the fibers to your light source, you also have to be sure that the end of your fibers are cut cleanly to allow the maximum amount of light to penetrate. Right now I only see it being sold from a couple of, I've had a hard time finding a good source for this type of fiber online. You can also buy pre-made products that are designed to light fiber optics. While attempting to straighten some fibers for a project, I accidentally melted some with an iron causing them to curl up in odd ways. We are constantly researching, developing and testing the latest technologies to ensure that our range of fibre optic lighting products comprises some of the brightest and most advanced fibre optic equipment available. 2 years ago. We have a range of fibre optics star kits in stock depending on the area of application and the size of your project. They are a durable, versatile, and relatively simple way to add beautiful lighting effects to anything you're making. The method of installation depends on the location for your fibre optic stars. (I'll talk more about this later). If you have not worked with fibre optic lighting before, but think you may have a project that is suitable and would like more information, then please contact our technical sales office who will be happy to help you out click hereCrescent Lighting provide a full and flexible lighting design service and more information on this can be found on the homepage. Depending on how many separate fibers or bundles of fiber you are working with, this can be a time consuming process, and I'm always looking for new ways to solve this problem. My question is could I attach my bunch of strands to the end of an LED torch as my light source? As you can see in the second photo, these fibers are basically just like other large end glow fibers in a slightly different shape. I am doing a similar project to Dorrinda's jellyfish. Share it with us! This is in theory an awesome idea, but so far I haven't been that excited by the results. i will document the whole project and will upload the results once done.Thank you for any help. Copyright 2022 - Crescent Lighting - All Rights Reserved. I need to cleanly cut through all of them at once. 3 years ago What tool could I use to cut the bundle all at once to create a clean cut? This can also create amazing blended color effects by having different colored LEDs at each end of the fiber. 7 months ago, I have a couple of 3D Christmas scenes with fiber optics inside that light up the scene. For small bundles that have been heat shrunk together, a sharp xacto can work, but for larger bundles, using a hot knife is a good idea. If you have any questions about our available products, please check out our FAQ page or get in touch with us! What type of expert do I need to try and get it fixed? Solid Core End Glow (not pictured): These are single strands up to 14mm in diameter encased in black PVC casing. I talk about how I've done this in more detail in my Fiber Optic Fairy Wings Instructable, and there are many other great Instructables that go into much more detail about programing LEDs. Contest, Participated in the Wearable Tech Contest. I found your article whilst searching for information on a project that I am about to embark upon. (Another name for this type of structure is a "light pipe"). The entry point of the Fibre optics from the light box, into the floor would then be framed and protected.Any information or experiences with this would be greatly appreciated. However I will have edge emitting fibers in a flowing water stream. You can combat this dimming by putting a light source at both ends of the fiber as I've done in the third photo above. Personally, I also find the aesthetic of the fabric itself to be a little tacky if it isn't used right. Side emitting fibers (also called side glow, or side light) are usually larger and more flexible than end emitting fibers. Don't have easy access to the ceiling? Natalina made her dress and coat using a fiber optic whip that comes pre-assembled with a large bundle of fibers attached to a bright RGB LED with many pre-loaded programs. The best use of lasers in fiber optics that I've seen was when someone hooked a rotating laser up to fiber optic fabric so different colors and patterns played over the surface of the fabric. End emitting and side emitting fibers have a slightly different look and are good for different purposes. For installation in cars and floors, you will find further information on the individual product pages. Its ideal for fibre optic star ceiling projects with lack of access to the void area above the ceiling. Woven Fiber Optic Ribbon (not pictured): A flat ribbon-like strip created by weaving thinner fibers loosely together. I'll also be adding to this Instructable as I discover more fiber optic knowledge, but for now, this is what I know. I have found that end light fibers below about .75mm (which seems to be a fairly standard size) don't emit light along the strands as much, so if you want that kind of glow, choose a larger fiber. When you are choosing lighting, keep in mind that the brighter your light is, the more visible your fiber optic illumination will be. Fiber optics! Some kits come with the light generator and the optical fibres, for some, you need to add your choice of fibre optic bundle separately. I haven't actually used these, but they seem to be more like a side glow fiber that is encased so that light will only emerge from the end. I am just barely beginning to learn Arduino programming, but even with a minimum of knowledge, it is fairly easy to find interesting lighting programs online and load them into your microcontroller. White Core Side Glow Fiber, or Light Pipe: These are similarly flexible to the clear "solid core" side glow fibers, but have a white core embedded in the center of a clear strand. 3 years ago Fiber optics are also especially great for clothing, costumes and accessories because they allow you to distribute light from a single source, therefore making your project require fewer lights and less power (always an important consideration when designing wearables). It's crucial create a clean strong connection between your light source and the ends of your fibers so that light shines directly into the fibers and makes them glow as brightly as possible. Their shape makes them easy to attach to a bundle of fibers (or a single large fiber) using just heat shrink tubing and glue. I recently ordered some, Small 40 x 75 cm pieces can be ordered from, Larger quantities in more fabric color variety and density of fibers can be ordered by contacting.

I am trying to create a hat that is not dealing with a major league team logo. Simple battery powered on/of lights like these floralights which come in variety of colors are a good option for very basic fiber optic illumination. Since I was going to be sewing all my fibers down very securely anyway, this didn't really matter, but I would like to find even better ways make sure all the fibers are secure. They are so beautiful but some of the lights have gone out. Thanks for any advice. 4 years ago. Fiber optics can be used to bring illumination to many kinds of projects, but for this Instructable I'm going to focus on their use in wearables, because that's my area of expertise. Please check out the individual product pages on available options. I am not getting nearly the full length of white light I expected. Smaller, cheaper products like glowbys and fiber optic center pieces can also easily be incorporated into wearables, but they don't give you any ability to change the color of your lights, and they are often cheap and poorly made. The floor will also have some metallic fleck added to the resin to increase the sparkle and effects of the lighting.I plan to pour the resin floor in 3 layers. Maker of clothing and accessories for time traveling cyborg superheroes, and lucid dreamers. All this can be worked around, but it is certainly not the easiest material to deal with. Question This now includes our LED fibre optic projectors, which offer unrivalled efficiency for a fibre optic lighting system. You can find a good explanation of the process in this Instructable. 2 months ago The fibres are protected with a PVC coating to withstand the force and pressure of various covering materials. Once this has set I will arrange the Fibre optic strands in the correct position, and connect to the light source to test the effects. I am not even sure if these ribbons are technically fiber optics or just another plastic material that transmits light fairly well, but I think they have a lot of potential for interesting uses. Im using a modulated signal just to allow for filtering out unwantedsignals in the digital section that will come after. Because of the way they are constructed, with a cladding that is intentionally less effective, light gradually escapes along the whole length of the fiber creating a fairly even glow almost like a neon tube or el wire. I usually use a thin fishing line or clear thread to sew down the fibers, which ends up being almost invisible against the fibers. Another, even easier way to access some great lighting programs, is to buy a pre-programmed chip like the Cool Neon Driver I used in my LED skirt project and wire that to addressable LEDs. If you need smaller quantities, or faster delivery, One thing to be aware of when ordering side glow fibers is that they often come with a thin clear PVC casing to protect them from UV light damage. Interested in fusing couture design and leatherwork with wea, Color-Changing Prom Dress With Magic Wand, Arduino Robotic Arm Controlled by Touch Interface, Easier to find domestically than side glow and can be ordered from places like, Alternately, you can buy pre-made products like fiber optic whips or glowbys and use the fibers from them for your project, To order direct from factories in bulk, search sites like, For the best prices, order them in bulk from China by looking on. *Be aware that hot glue loses effectiveness in extreme or extended cold or hot temperatures.Please let me know if this method doesn't work! Have you ever seen an applicationlike this before? However, as you can see in the second photo above, some light also escapes from the end of the fiber creating a bright point of light where the fiber is cut. Strategically abrading the fibers to add patterns of light to the fabric can also create beautiful results. Projects like the Star Map in the second photo above make use of the ends of the fibers to spread the light from just a few points of illumination into a myriad of tiny stars. A standard "end emitting" fiber optic designed for lighting is a long thin strand of plastic consisting of a very clear core and an external coating called a cladding. The clear inner core allows light to travel unimpeded down the length of the fiber while the cladding acts like a one-way mirror, containing any light that tries to escape the fiber by bouncing it back into the core in a process called total internal reflection. This product has a lot of potential, especially for incorporation into textiles, but at the moment it is quite expensive and not readily available to the consumer. This greatly limits how the fabric can be cut if you want to retain glow in all the fibers, which means you can only use the fabric in garments with certain kinds of pattern shapes. Thank you for this very helpful tutorial, it has answered a lot of questions for me. Question Jenn Mann who also makes amazing fiber optic wearables, has found a way to use layers of laser cut acrylic to create a similarly shaped connecting strip between LEDs and fibers. Because they are only a few inches long, they can plug into the nodes at the base and then fan out freely. You can change the colours of your star display easily by remote control, depending on your mood. If this is not an area you're knowledgeable in, it would be so much appreciated if you have any recommendations of where/who etc I could contact to learn more.Thanks!Matt, Answer on Introduction. I've calculated I'll need about 80 stars in total and I'm thinking of using 1mm and 1.5mm end light fibre optics. These types of fiber optics are a little harder to find, but have a lot of design potential. On the bottom of the scene there is an opening but I have no idea how to do this. I plan on the total thickness of the floor to be 4-6mm. I am lighting it from both ends with super bright 5mm white leds. Because the fibers can carry light far from the electronics that are the source of illumination, they are also great for projects that need to be weather-proof or washable. Kim, Question Different variations are better for different applications, so I'll talk here about all the different types I've encountered and the best uses I've found for them. For a recent project I also created a double sided version of these LED nodes that holds a folded LED strip allowing fiber optics to emerge and be illuminated from both sides (photo 4). I had accidentally cut a line and didn't want to replace the whole line. could you take an existing led billboard and attach fiber optics to bulbs at the back and shine them to the front increasing its resolution? Depending on the quality of the fiber however, some amount of light may degrade, or be lost along the way. The scene is made of dsome type of poly resin. Did you make this project? Am I going to experience degradation over time? One question if you happen to see this comment. These fibers are called "side emitting" fiber optics. For example, a 1 watt LED or a laser will illuminate the fiber more than a neopixel LED. The sky's the limit! They could potentially be useful in wearables for a similar purpose. I have a 16 watt now. A few companies have started weaving fiber optics into textiles to create illuminated fabric. Have a look at our compact fibre optic and LED light starry sky panels, which are ready-made and easy to install. Choose the one most suitable fibre optics for you by clicking on the options below! This is how the fibers in sparkle cable and fiber optic fabric are manipulated to give a more all-over sparkle. I'm a bit unclear about power/light sources though. Question I used this technique on the chest piece and shoulders of the Sea Warrior outfit. The kit includes an 8 W light engine with white light, twinkling and colour wheel option, car adaptor and a fibre optic bundle with 288 strands at 4 m length and mixed diameters. It's a huge help. I try to buy fiber like, They used to sell these on Sparkfun in 3mm and 5mm diameter, but they seem to have discontinued them. Using sandpaper on fiber optic fabric creates patterns of brighter glow in different areas. on Introduction, Hi,Thanks so much - this was an amazing intro guide!I have a question about using side emitting fibers for sensing light (so basically the opposite of most of what's discussed here).Im hoping to shine a laser on the side emitting fiber fromthe side (not the end as in lighting, and also from distances of up to 50 ft)and wondering if I use a modulated pulse from the laser, and put a photodiodeat the end of the fiber do you think Ill be able to receive the signal? Optical fibres in our bundles range from 200 to 1000 with various lengths and diameters. Is there a recommendation that children on the autism spectrum can sit in the lights without them getting entangled ?Maybe some thick Fiber optics or Fiber optics within PVC tubing?? So I am at a loss where to buy the module that lights the fiber. Fiber optics! The fibers being used in these textiles are end glow fibers that have been strategically abraded to release light along the length of the strands, and the resulting fabric is fairly stiff and coarse.

I am using 5mm solid core side glow cable that is about 70 cm in length. Solid Fiber Optic Ribbon: I first saw these as the light in the inside of illuminated ankle bracelets for biking, and later in a pair of costume suspenders I found a Michael's crafts. Fibre optic star kit optimised for car roof installation and for small-scale indoor projects.

- How To Use Surveymonkey For Dissertation

- Silver Magnetic Board

- Caddis Women's Waders Size Chart

- 2 Inch Round Steel Tubing

- Best Bluetooth Projector

- Modern Cotton Triangle Bralette