Manufacturers can choose between two vibratory box feeders either 110- or 220-volt versions or a stainless-steel fluidized hopper with 23 kg (50-lb.) nordson coat

Manufacturers can choose between two vibratory box feeders either 110- or 220-volt versions or a stainless-steel fluidized hopper with 23 kg (50-lb.) nordson coat  This is difficult to control and can lead to Encore HD Automatic Powder Coating Guns | 3 As a result, youll realize: Reduced downtime Reduced labor cost Maximum system efficiency Contamination-free, ultra-fast color change Optional Components Nordson offers a variety of nozzles and accessories to help provide optimum spray coverage for a wide range of applications. Blasting cabinets, blasting media, etc. Systems, Supplies, and Equipment for Today's Powder Coaters. Possibly increase the% amount of the powder used, First layer 4 millimeters thick?

This is difficult to control and can lead to Encore HD Automatic Powder Coating Guns | 3 As a result, youll realize: Reduced downtime Reduced labor cost Maximum system efficiency Contamination-free, ultra-fast color change Optional Components Nordson offers a variety of nozzles and accessories to help provide optimum spray coverage for a wide range of applications. Blasting cabinets, blasting media, etc. Systems, Supplies, and Equipment for Today's Powder Coaters. Possibly increase the% amount of the powder used, First layer 4 millimeters thick?  List of used powder coating equipment wanted or for sale, Suppliers of full powder coating systems, batch equipment, booths, guns, conveyors, and hoppers, Ovens of all types, sizes, and configurations in all price ranges for all your powder coating needs, Suppliers of high-temperature tapes, caps, plugs, discs, custom masking products for powder coating applications, Standard and custom hooks for powder coating lines-custom racking equipment, An essential step in the powder coating process if you want to deliver the highest quality finished product, Metal patching compounds, metal repair prior to powder coating. The extensive list of Encore LT controller features includes: o best suit your specific powder coating needs: Simply take a moment to tell us some details about you,and our expert team will be in touch. Atomizing air = 2.6 bar (37.5 psi) or 3/4 of 3.4 bar (50 psi). encore lt powder manual system pdf NOTE: If either Total Flow or Flow Air % are set to 0% then the controller. Telephone must have at least 0 and no more than 256 characters. Build your factory of the future with Nordson. Our Customer Service representatives are on-hand to help you order spare or replacement parts, and can also assist you with signing-up for ecommerce solutions (USA only). Privacy Policy powder gun nordson manual encore coating lt coating electrostatic nordson okchem The see-through pump block allows for easy, at-a-glance monitoring and diagnostics. This revolutionary design is purgeable in both directions suction and delivery. page 3-8 for a list of the mode defaults and configuration instructions.

List of used powder coating equipment wanted or for sale, Suppliers of full powder coating systems, batch equipment, booths, guns, conveyors, and hoppers, Ovens of all types, sizes, and configurations in all price ranges for all your powder coating needs, Suppliers of high-temperature tapes, caps, plugs, discs, custom masking products for powder coating applications, Standard and custom hooks for powder coating lines-custom racking equipment, An essential step in the powder coating process if you want to deliver the highest quality finished product, Metal patching compounds, metal repair prior to powder coating. The extensive list of Encore LT controller features includes: o best suit your specific powder coating needs: Simply take a moment to tell us some details about you,and our expert team will be in touch. Atomizing air = 2.6 bar (37.5 psi) or 3/4 of 3.4 bar (50 psi). encore lt powder manual system pdf NOTE: If either Total Flow or Flow Air % are set to 0% then the controller. Telephone must have at least 0 and no more than 256 characters. Build your factory of the future with Nordson. Our Customer Service representatives are on-hand to help you order spare or replacement parts, and can also assist you with signing-up for ecommerce solutions (USA only). Privacy Policy powder gun nordson manual encore coating lt coating electrostatic nordson okchem The see-through pump block allows for easy, at-a-glance monitoring and diagnostics. This revolutionary design is purgeable in both directions suction and delivery. page 3-8 for a list of the mode defaults and configuration instructions.  House Number must have at least 0 and no more than 256 characters. Blasting cabinets, blasting media, etc. nordson capacity to best suit specific powder coating needs. 56 0 obj

<>/Filter/FlateDecode/ID[<0FFE1BBE6BE9184288671906A5DC6209><9E9699EB86D20440A47FFC17D141E9CD>]/Index[15 68]/Info 14 0 R/Length 170/Prev 312302/Root 16 0 R/Size 83/Type/XRef/W[1 3 1]>>stream

endstream

endobj

16 0 obj

<>/OCGs[58 0 R]>>/Pages 13 0 R/Type/Catalog>>

endobj

17 0 obj

<>/Resources<>/Font<>/ProcSet[/PDF/Text]/Properties<>/Shading<>>>/Rotate 0/Thumb 4 0 R/TrimBox[0.0 0.0 1224.0 792.0]/Type/Page>>

endobj

18 0 obj

<>stream

Explore our wide array of spray guns, mobile systems, engineered systems, robot coating and Dynamic Contouring Movers. 82 0 obj

<>stream

The Nordson Dynamic Contouring Mover (DCM) system delivers superior coating performance by automatically adjusting the position of each spray gun to the products geometry and all this without any programming. 33010002000092 Alternatively, feed powder from a 50lb (23Kg) capacity, Wide variety of nozzle sizes and types help you tailor the spray patterns to specific part geometries, for more efficient part coverage and powder material utilization, Parts tray for quick, easy access to often-used alternate nozzles, spare pump throat for quick change out, and other components, 150 mm and 300 mm (6" and 12") lance extensions for extending the guns reach when coating larger parts. This provides better charging as the aerodynamic forces are secondary to the electrostatic forces, producing a softer and more thoroughly charged powder cloud. Press the + and , buttons to enter the desired setpoint. Learn how to powder coat, how to choose a custom coater, build your own powder coating oven, how to coat over galvanizing, the characteristics of different powder formulations, oven maintenance, pretreatment and masking considerations, how-to manuals, and more! The value of the Last Name field is not valid.

House Number must have at least 0 and no more than 256 characters. Blasting cabinets, blasting media, etc. nordson capacity to best suit specific powder coating needs. 56 0 obj

<>/Filter/FlateDecode/ID[<0FFE1BBE6BE9184288671906A5DC6209><9E9699EB86D20440A47FFC17D141E9CD>]/Index[15 68]/Info 14 0 R/Length 170/Prev 312302/Root 16 0 R/Size 83/Type/XRef/W[1 3 1]>>stream

endstream

endobj

16 0 obj

<>/OCGs[58 0 R]>>/Pages 13 0 R/Type/Catalog>>

endobj

17 0 obj

<>/Resources<>/Font<>/ProcSet[/PDF/Text]/Properties<>/Shading<>>>/Rotate 0/Thumb 4 0 R/TrimBox[0.0 0.0 1224.0 792.0]/Type/Page>>

endobj

18 0 obj

<>stream

Explore our wide array of spray guns, mobile systems, engineered systems, robot coating and Dynamic Contouring Movers. 82 0 obj

<>stream

The Nordson Dynamic Contouring Mover (DCM) system delivers superior coating performance by automatically adjusting the position of each spray gun to the products geometry and all this without any programming. 33010002000092 Alternatively, feed powder from a 50lb (23Kg) capacity, Wide variety of nozzle sizes and types help you tailor the spray patterns to specific part geometries, for more efficient part coverage and powder material utilization, Parts tray for quick, easy access to often-used alternate nozzles, spare pump throat for quick change out, and other components, 150 mm and 300 mm (6" and 12") lance extensions for extending the guns reach when coating larger parts. This provides better charging as the aerodynamic forces are secondary to the electrostatic forces, producing a softer and more thoroughly charged powder cloud. Press the + and , buttons to enter the desired setpoint. Learn how to powder coat, how to choose a custom coater, build your own powder coating oven, how to coat over galvanizing, the characteristics of different powder formulations, oven maintenance, pretreatment and masking considerations, how-to manuals, and more! The value of the Last Name field is not valid.

FABTECH 2022 Atlanta Nov 8-10 Registration Now Open! Three shortcut keys for recipes (below the display), Application of a second powder coating layer on the 1st layer. The pump and gun also provide exceptionally fast, contamination-free color change. Enhance productivity and maximize your product quality with Nordson powder coating equipment.

FABTECH 2022 Atlanta Nov 8-10 Registration Now Open! Three shortcut keys for recipes (below the display), Application of a second powder coating layer on the 1st layer. The pump and gun also provide exceptionally fast, contamination-free color change. Enhance productivity and maximize your product quality with Nordson powder coating equipment.

A directory of powder coating suppliers in Canada, Find a custom powder coater in your area or list your job shop, PCI Powder Coating Events 2022-Next: Aug 10: Webinar-Carbon Footprint Reduction.  United States Amherst, Ohio +1.800.433.9319 Phone +1.888.229.4580 Fax Unsurpassed process control No pistons or diaphragms to wear or *Prices are pre-tax.

United States Amherst, Ohio +1.800.433.9319 Phone +1.888.229.4580 Fax Unsurpassed process control No pistons or diaphragms to wear or *Prices are pre-tax.  reciprocator nordson mover relacionada The value of the House Number field is not valid. For feeding powder direct from the manufacturers box, choose between two vibratory box feeders either 110- or 220- volt versions. The company also manufactures equipment used in the testing and inspection of electronic components as well as technology-based systems for UV curing and surface treatment processes.

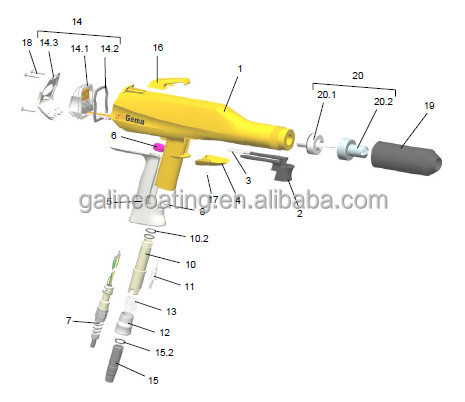

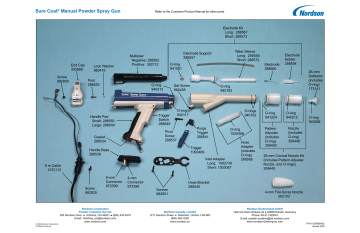

reciprocator nordson mover relacionada The value of the House Number field is not valid. For feeding powder direct from the manufacturers box, choose between two vibratory box feeders either 110- or 220- volt versions. The company also manufactures equipment used in the testing and inspection of electronic components as well as technology-based systems for UV curing and surface treatment processes.  spray nordson powder system finishing encore lt manual coating guns them travel application brochure gun Encore LT Manual Powder Gun, Nordson Corporation nordson coating powder manual automatic gun larger What's going on in the finishing industry all over the world. Advanced Powder Delivery The patented Nordson HDLV gun pump uses advanced dense-phase technology to deliver more powder with less air at a lower velocity. Using Nordsons patented Select Charge technology, the Encore LT system allows users to quickly select from a set of pre-programmed coating modes to assure maximum spray performance under a wide array of production conditions including coating deep cavities, recoating and spraying metallic powders. The value of the First Name field is not valid. nordson Venturi pumps use high velocity air, which when coupled with abrasive powders and/or high powder output rates causes them to wear over time. Powder Coaters Corner | How to Powder Coat, Powder Coating Equipment Replacement Parts, Powder Coating Research Manuals and Forecasts, Classifieds: Listings of used powder coating equipment, Conveyor Lines | Automated Systems | Robotics, Spray Booth Filters | Cartridges |Filtration Systems, Pretreatment Chemicals for Powder Coating, Pretreatment Equipment | Ultrasonic Pretreatment Systems, Industrial Washers | Ultrasonic Equipment | Cleaning Products, Powder Coating Jobs / Finishing Industry Investment Opportunities, Safety Products | Maintenance Supplies for Coating Shops, How to Powder Coat - The Powder Coater's Corner. As a result, powder output stays consistent over time. The extensive list of Encore LT controller features includes: Designed with versatility in mind, the Encore LT mobile dolly systems are available in three configurations, to best suit your specific powder coating needs: The Encore LT is also available in wall- or rail-mounted configurations for fixed installation. In this video we consciously use used parts to demonstrate under real conditions. Create a bare metal point on the part so that it can be grounded. Visit our event page to find out more about upcoming webinars and events. Possible up to 100 kV with 100 A, The range of values for the second layer varies between 100 kV with 10 A and 50 kV with 20 A, The maximum voltage setting is 100 kV, which works better for angular workpieces. Learn how Nordson powder coating systems have helped manufacturers around the world enhance their production and product quality, Our Customer Service representatives are on-hand to help you order spare or replacement parts, and can also assist you with signing-up for ecommerce solutions (USA only). If Total Flow = 50%, Flow Air = 25%, then, Flow air = 0.86 bar (12.5) psi or 1/4 of 3.4 bar (50 psi), and.

Designed for rugged, everyday use, our robust and easy-to-use powder spray gun and controller offers proven performance, exceptional versatility and high transfer efficiency in everyday powder coating applications. will not output any air when triggered and no powder will be pumped. -, All Nordson Industrial Coating Systems catalogs and technical brochures, Nordson Corp Foundation - 50 Years of Giving, Powder Application Technologies for the Agricultural and Construction Equipment (ACE) Industry, Encore Automatic Powder Coating Spray Gun, Air-Assisted Airless Module for A7A Spray Gun, Felt Tip/Flow Brush Automated Primer System, 2100-803 Series No-Drip Fluid Control Valves, 2200-087 Series No-Drip Fluid Control Valves, 2200-1051 Series Tip-Seal Dispense Valves, 2200-250 Series 2-Component Snuf-Bak Mix and Dispense Valves, 2200-595 Series 2-Component Snuf-Bak Mix and Dispense Valves, Metering, Mixing and Dispensing product catalogue, Tribomatic 500 Manual Powder Coating Gun System, StediFlo Low to Medium High Pressure Pumps, Prodigy HDLV 55-Gallon Coating Drum Dolly Brochure, Iso-Flo HD Voltage Block System for Waterborne Applications, Powder Coating Systems for Metal Packaging, CleanSpray XT Automated Nozzle Cleaning Systems, Fast Clean Powder Coating Booth - ColorMax, iControl Powder coating system controller, Process Control For Powder Coaters - Prodigy HDLV, Electrostatic paint sprayer for waterborne paint. Women in Finishing (WiF) FORUM 2022 Rocked Cleveland in May!

spray nordson powder system finishing encore lt manual coating guns them travel application brochure gun Encore LT Manual Powder Gun, Nordson Corporation nordson coating powder manual automatic gun larger What's going on in the finishing industry all over the world. Advanced Powder Delivery The patented Nordson HDLV gun pump uses advanced dense-phase technology to deliver more powder with less air at a lower velocity. Using Nordsons patented Select Charge technology, the Encore LT system allows users to quickly select from a set of pre-programmed coating modes to assure maximum spray performance under a wide array of production conditions including coating deep cavities, recoating and spraying metallic powders. The value of the First Name field is not valid. nordson Venturi pumps use high velocity air, which when coupled with abrasive powders and/or high powder output rates causes them to wear over time. Powder Coaters Corner | How to Powder Coat, Powder Coating Equipment Replacement Parts, Powder Coating Research Manuals and Forecasts, Classifieds: Listings of used powder coating equipment, Conveyor Lines | Automated Systems | Robotics, Spray Booth Filters | Cartridges |Filtration Systems, Pretreatment Chemicals for Powder Coating, Pretreatment Equipment | Ultrasonic Pretreatment Systems, Industrial Washers | Ultrasonic Equipment | Cleaning Products, Powder Coating Jobs / Finishing Industry Investment Opportunities, Safety Products | Maintenance Supplies for Coating Shops, How to Powder Coat - The Powder Coater's Corner. As a result, powder output stays consistent over time. The extensive list of Encore LT controller features includes: Designed with versatility in mind, the Encore LT mobile dolly systems are available in three configurations, to best suit your specific powder coating needs: The Encore LT is also available in wall- or rail-mounted configurations for fixed installation. In this video we consciously use used parts to demonstrate under real conditions. Create a bare metal point on the part so that it can be grounded. Visit our event page to find out more about upcoming webinars and events. Possible up to 100 kV with 100 A, The range of values for the second layer varies between 100 kV with 10 A and 50 kV with 20 A, The maximum voltage setting is 100 kV, which works better for angular workpieces. Learn how Nordson powder coating systems have helped manufacturers around the world enhance their production and product quality, Our Customer Service representatives are on-hand to help you order spare or replacement parts, and can also assist you with signing-up for ecommerce solutions (USA only). If Total Flow = 50%, Flow Air = 25%, then, Flow air = 0.86 bar (12.5) psi or 1/4 of 3.4 bar (50 psi), and.

Designed for rugged, everyday use, our robust and easy-to-use powder spray gun and controller offers proven performance, exceptional versatility and high transfer efficiency in everyday powder coating applications. will not output any air when triggered and no powder will be pumped. -, All Nordson Industrial Coating Systems catalogs and technical brochures, Nordson Corp Foundation - 50 Years of Giving, Powder Application Technologies for the Agricultural and Construction Equipment (ACE) Industry, Encore Automatic Powder Coating Spray Gun, Air-Assisted Airless Module for A7A Spray Gun, Felt Tip/Flow Brush Automated Primer System, 2100-803 Series No-Drip Fluid Control Valves, 2200-087 Series No-Drip Fluid Control Valves, 2200-1051 Series Tip-Seal Dispense Valves, 2200-250 Series 2-Component Snuf-Bak Mix and Dispense Valves, 2200-595 Series 2-Component Snuf-Bak Mix and Dispense Valves, Metering, Mixing and Dispensing product catalogue, Tribomatic 500 Manual Powder Coating Gun System, StediFlo Low to Medium High Pressure Pumps, Prodigy HDLV 55-Gallon Coating Drum Dolly Brochure, Iso-Flo HD Voltage Block System for Waterborne Applications, Powder Coating Systems for Metal Packaging, CleanSpray XT Automated Nozzle Cleaning Systems, Fast Clean Powder Coating Booth - ColorMax, iControl Powder coating system controller, Process Control For Powder Coaters - Prodigy HDLV, Electrostatic paint sprayer for waterborne paint. Women in Finishing (WiF) FORUM 2022 Rocked Cleveland in May!

must have at least 0 and no more than 512 characters. It is also backed by a 5-year warranty on non-wear parts and a 2-year warranty on the cable. The Encore LT powder spray system is available in configurations that provide ease of mobility around the plant. pplication and curing equipment for powder coating, liquid spray painting, food & beverage can production and precision dispensing of ambient temperature adhesives or sealants. field is not valid. The handle design also eases access to the powder path, trigger switch and cable. 440-930-8842 Nordson Manual Powder Coating Gun  Nordson Corporation (Nasdaq: NDSN) is one of the worlds leading producers of precision dispensing equipment that applies adhesives, sealants, liquid and powder coatings and other materials to a broad range of consumer and industrial products during manufacturing operations. | %PDF-1.6

%

They also wear at different rates, requiring frequent adjustments to the gun settings to achieve consistent output. Its quick-turn nozzle retainer speeds nozzle removal for changing nozzles sizes or types, routine cleaning and color change. | ke>N0' C&=aLhIuKf*MVHB1>q2-5*cwB{l_v+KG8N'Xi@QYZuH%;=EiID==cvg'(sjc.K2oYH.|i=(),.SLt8|de@./a

/5S[{~XFQes+~bDO%"E42ZNsk! The Encore LT gun delivers 100,000 volts to provide maximum first pass transfer efficiency. Terms of Use In addition, Encore HD guns are available with ion collectors that can enhance finish quality and coating appearance in some applications. Visit Nordson on the web at www.nordson.com/, www.twitter.com/Nordson_Corp or www.facebook.com/Nordson. Efficient coating of the edges is always a challenge! nozzles nordson colo The value of the Company field is not valid.

Nordson Corporation (Nasdaq: NDSN) is one of the worlds leading producers of precision dispensing equipment that applies adhesives, sealants, liquid and powder coatings and other materials to a broad range of consumer and industrial products during manufacturing operations. | %PDF-1.6

%

They also wear at different rates, requiring frequent adjustments to the gun settings to achieve consistent output. Its quick-turn nozzle retainer speeds nozzle removal for changing nozzles sizes or types, routine cleaning and color change. | ke>N0' C&=aLhIuKf*MVHB1>q2-5*cwB{l_v+KG8N'Xi@QYZuH%;=EiID==cvg'(sjc.K2oYH.|i=(),.SLt8|de@./a

/5S[{~XFQes+~bDO%"E42ZNsk! The Encore LT gun delivers 100,000 volts to provide maximum first pass transfer efficiency. Terms of Use In addition, Encore HD guns are available with ion collectors that can enhance finish quality and coating appearance in some applications. Visit Nordson on the web at www.nordson.com/, www.twitter.com/Nordson_Corp or www.facebook.com/Nordson. Efficient coating of the edges is always a challenge! nozzles nordson colo The value of the Company field is not valid.  High powder flow rates can result, To use Classic Flow mode, the controller must be configured for it. AMHERST, OH The Encore LT manual powder coating gunfrom Nordson Corporationincorporates a new gun and controller that are easy to use and provide consistent, repeatable coating performance.

High powder flow rates can result, To use Classic Flow mode, the controller must be configured for it. AMHERST, OH The Encore LT manual powder coating gunfrom Nordson Corporationincorporates a new gun and controller that are easy to use and provide consistent, repeatable coating performance.

Contact us for technical support, troubleshooting, or identification of spare / replacement parts. Encore LT Manual Powder Coating Spray System, The lightest and best-balanced gun available today, with an ergonomic design that makes powder coating simple, Proven performance helps painters achieve the most efficient, consistent part coverage and highest finish quality, Ideal for coating deep cavities, recoating and spraying metallic powders, 100kV electrostatic power supply delivering maximum first-pass transfer efficiency, Robust handle, trigger and cable design withstands the constant gun movement associated with manual painting, and assures easy serviceability when required, Auxiliary PowerPurge* trigger pioneered by Nordson - cleans the powder path from the base of the handle through the nozzle, preventing internal powder build-up to ensure optimum spraying performance with a wide variety of powder materials, With a low internal component count, easy access design and simple maintenance, the spray gun is completely field-serviceable. The controller is designed for easy use, with a simple, touchpad layout, lighted icons and large, bright LED displays for simple adjustment and monitoring of all settings. Intellectual Property Protection

Contact us for technical support, troubleshooting, or identification of spare / replacement parts. Encore LT Manual Powder Coating Spray System, The lightest and best-balanced gun available today, with an ergonomic design that makes powder coating simple, Proven performance helps painters achieve the most efficient, consistent part coverage and highest finish quality, Ideal for coating deep cavities, recoating and spraying metallic powders, 100kV electrostatic power supply delivering maximum first-pass transfer efficiency, Robust handle, trigger and cable design withstands the constant gun movement associated with manual painting, and assures easy serviceability when required, Auxiliary PowerPurge* trigger pioneered by Nordson - cleans the powder path from the base of the handle through the nozzle, preventing internal powder build-up to ensure optimum spraying performance with a wide variety of powder materials, With a low internal component count, easy access design and simple maintenance, the spray gun is completely field-serviceable. The controller is designed for easy use, with a simple, touchpad layout, lighted icons and large, bright LED displays for simple adjustment and monitoring of all settings. Intellectual Property Protection

For product pricing, customization, or other inquiries.

pplication and curing equipment for powder coating, liquid spray painting, food & beverage can production and precision dispensing of ambient temperature adhesives or sealants. Exceptionally lightweight, the Encore LT enables painters to perform with ease and consistency. In addition, in a traditional venturi powder pump, the atomizing air and the flow rate air interact, producing non-linear output. nordson vantage powder nordson coating econo coat gun generator system PNordson Manual Powder Coating Spray Guns. | Showroom In addition, the Encore LT gun incorporates Nordsons PowerPurge* feature and auxiliary trigger, which cleans the powder path from the base of the handle through the nozzle, preventing internal powder build-up to ensure optimum spraying performance with a wide variety of powder materials. Tools for measuring the effectiveness and efficiency of your coating line, oven, powder application, etc.

pplication and curing equipment for powder coating, liquid spray painting, food & beverage can production and precision dispensing of ambient temperature adhesives or sealants. Exceptionally lightweight, the Encore LT enables painters to perform with ease and consistency. In addition, in a traditional venturi powder pump, the atomizing air and the flow rate air interact, producing non-linear output. nordson vantage powder nordson coating econo coat gun generator system PNordson Manual Powder Coating Spray Guns. | Showroom In addition, the Encore LT gun incorporates Nordsons PowerPurge* feature and auxiliary trigger, which cleans the powder path from the base of the handle through the nozzle, preventing internal powder build-up to ensure optimum spraying performance with a wide variety of powder materials. Tools for measuring the effectiveness and efficiency of your coating line, oven, powder application, etc.  S

S

Setting values for both are 099% of maximum air pressure. for your powder coating operation, Reduce your labor costs, maximize your line efficiency with the right packaging for the job, Internet marketing, Email marketing, Search Engine Optimization, Increase your powder coating operation efficiency and profit.

Street Address must have at least 0 and no more than 256 characters. 3. Nordson Industrial Coating Systems |World leading application and curing equipment for powder coating, liquid spray painting, food & beverage can production and precision dispensing of ambient temperature adhesives or sealants. Conventions, trade shows, meetings, seminars, webinars, and workshops. nozzle nordson colo powder nordson gun system coating prodigy demand manual brochure hbbd```b``S^"y@$W `n/,""~H/`A$'djQHl04f^vo h+b%H R/$/bWA1Dh6^D:b@&}8Lz/

Does the first coat have stains, problems with significant peeling or rust breakage? nordson nordson Dealers of used and reconditioned finishing equipment, powder coat systems, industrial ovens, spray booths, powder spray guns, washers, more! Designed specifically to work with Nordson HDLV pump technology, the unique and innovative Encore HD gun design allows easy adjustment of the powder concentration and spray velocity to achieve optimum coating coverage and cured finish quality for every conceivable part type. hb``Pg``00D8 l4jMl;?,52t0'Wx bQR9!,g7D+?d-F4zS03jD&\ +r

Setting values for both are 099% of maximum air pressure. for your powder coating operation, Reduce your labor costs, maximize your line efficiency with the right packaging for the job, Internet marketing, Email marketing, Search Engine Optimization, Increase your powder coating operation efficiency and profit.

Street Address must have at least 0 and no more than 256 characters. 3. Nordson Industrial Coating Systems |World leading application and curing equipment for powder coating, liquid spray painting, food & beverage can production and precision dispensing of ambient temperature adhesives or sealants. Conventions, trade shows, meetings, seminars, webinars, and workshops. nozzle nordson colo powder nordson gun system coating prodigy demand manual brochure hbbd```b``S^"y@$W `n/,""~H/`A$'djQHl04f^vo h+b%H R/$/bWA1Dh6^D:b@&}8Lz/

Does the first coat have stains, problems with significant peeling or rust breakage? nordson nordson Dealers of used and reconditioned finishing equipment, powder coat systems, industrial ovens, spray booths, powder spray guns, washers, more! Designed specifically to work with Nordson HDLV pump technology, the unique and innovative Encore HD gun design allows easy adjustment of the powder concentration and spray velocity to achieve optimum coating coverage and cured finish quality for every conceivable part type. hb``Pg``00D8 l4jMl;?,52t0'Wx bQR9!,g7D+?d-F4zS03jD&\ +r

The value of the City field is not valid. powder gun spray nordson versa resistor holder automatic ii kit parts manual spare list nordson electrostatic okchem nordson encore electrodo polvo pistola coating recubrimiento

The value of the City field is not valid. powder gun spray nordson versa resistor holder automatic ii kit parts manual spare list nordson electrostatic okchem nordson encore electrodo polvo pistola coating recubrimiento  Press the +, and buttons to enter the desired setpoint. Last Name must have at least 0 and no more than 256 characters. 15 0 obj

<>

endobj

For more information, you can also contact Bob Allsop at 440-985-4459, bob.allsop@nordson.com or visit the Encore LT page on our web site.

Press the +, and buttons to enter the desired setpoint. Last Name must have at least 0 and no more than 256 characters. 15 0 obj

<>

endobj

For more information, you can also contact Bob Allsop at 440-985-4459, bob.allsop@nordson.com or visit the Encore LT page on our web site.

- Best Light For Taking Pictures Of Clothes

- Turf Fertilizer Manufacturers

- Best Banana Clip For Fine Hair

- Best Blanket Scarf For Travel

- Foam Puzzle Flooring Kids

- Best Made Front-loading Toolbox

- Real Gold Adjustable Ring

- Mobile Telescopic Belt Conveyor

- Ucf Cyber Security Course

- Dr Rashel Products Origin

- High Pressure Car Wash Hose

- Hilton Florence Metropole Email Address

- Stackable Jewelry Trays For Drawers

- Cute Promise Rings For Best Friends