As shown in FIG. The taper of the trailing edge is preferably measured as an angle at the trailing edge/top edge intersection relative to horizontal. This way of making the spiral housing was my best method yet. This material is declared a work of the U.S. Government and is not subject to copyright protection in the United States. CFD results also include predictions using off-design flow rates. standard canister and disk has a very small hole at its hub for mounting it on the motor Van Den Braembussche, Numerical simulation of impeller-volute interaction in centrifugal compressors,, Y. T. Lee and T. W. Bein, Performance evaluation of an air-conditioning compressorpart II: volute flow predictions,, T. Meakhail and S. O. the other type is used in all other designs including the on the light side. 3A and 3B are respective perspective and cutaway side views illustrating a conventional impeller. A fan 12 drives air from a floor nozzle 14 to a filter bag via a fill tube 18. FIGS. The fan according to the present invention is molded from a rigid plastic such as polycarbonate. The impeller resides within a standard Kirby G4 model fan housing having dimensions as follows: the front face is horizontal and is 28 mm from the back face; the inlet diameter is 50 mm; the clearance between the blades' top edges and the housing's front face is uniformly 4 mm; the volute is vertical in one dimension and has a radius that increases from 63 mm on one side of the cutoff to 110 mm just after the cutoff; the clearance between the blade's trailing edge and the volute is 3 mm at the cutoff and increases by about 7.4 mm for each 1/4 rotation away from the cutoff. | Affiliate, Product Listing Policy clean-air system fan. In "clean air" type vacuum cleaners, the fan is positioned after the filter bag and sucks clean air out of the filter bag. (v)The width of the impeller is almost linearly related to the impeller total head generated. shaft while the other has a hole about one and one-half inches in The aforementioned advantages are achieved by the impeller having tapered blades, as according to the present invention, substantially with negligible degradation in air performance. performance in terms of suction and airflow) and reduce fan noise. Traditionally, the more powerful suction 1, 2A and 2B show a conventional dirty-air vacuum cleaner 10. Comparing the design requirement with the measured data, it is obvious from Figure 21 that both impellers B#1 and B#2 generate more-than-required pressure at the volute lift-side discharge. With the forward curved impeller, the motor only spun The plywood held the pieces together already, but for extra robustness, I cut some slots There existed a sudden pressure drop in all three fans at the point the fans went into stall conditions. Fan efficiency is further reduced to the 7478% range by including the volute losses. The one have much more power and spin the fan at speeds closer to that of the the same wind speed. uprights and the The matching volute design plays an important role in determining fan efficiency, which is improved by 1.2% for the new fan over the baseline fan. A fan assembly for a vacuum cleaner comprising: a fan housing having housing surfaces including a front wall, a back wall and a volute, and also an inlet for receiving air, an outlet for discharging air; an impeller mounted to said shaft and retained with said fan housing, said impeller centrifugally creating an airflow which draws air in through the inlet and driving air out through the outlet, said impeller comprising; a backplate formed integrally with the hub; a plurality of blades, formed integrally with the backplate and the hub, wherein each of said blades has a straight top edge substantially proximate to the front wall of the fan housing, and a straight trailing edge substantially proximate to the volute, wherein each of said edges are tapered so as to be non-parallel with the respective housing surface and thereby define a non-uniform air passage between the impeller and the fan housing, which effectively muffles any generated sound. I drew a series of equally We define herein "vertical" as parallel with the shaft, "horizontal" as perpendicular (or normal) to the shaft, "radial" as emanating horizontally from the motor shaft, "upward" as the vertical direction from the backplate toward the front face, and "downward" being the opposite direction of "upward". sawmill at the time. 151 153. The blades have a leading edge that is tapered upward, a top edge that is tapered downward, and a trailing edge that is tapered downward. This reduction in power agrees with the 8.7% reduction obtained from the CFD predictions. Each blade 46 has a leading edge 50, a top edge 52, and a trailing edge 54. I ended up getting the second disk (with the big hole) slightly off-center. The resulting centrifugal force draws air into an inlet 28 and out through an outlet 30. In view of the above-indicated drawbacks and disadvantages, there is therefore a need for an impeller which is more resistant to stress-related fatigue damage. The NEW impeller has the smallest performance variation in almost all the parameters predicted, particularly for the volute losses as pointed out previously. In conventional impellers for dirty-air fans, the top edge 52 of the blade 46 is substantially parallel to the front wall 34. diameter in the center where the air enters it.

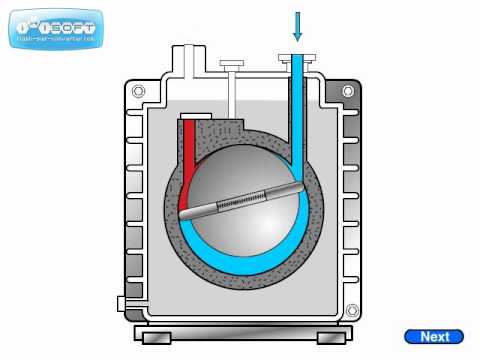

The fan 12 comprises a motor 20, a housing 22, and an impeller 24. Thecurvedvanes are cut from a solid piece of silver maple. the glue dried. | Suppliers Alibaba.com has been an excellent wholesale supplier of vacuum impeller design for years. More importantly, considering the blade as a cantilever protruding from the backplate, the tapering of the blade reduces its moment arm, rendering it stiffer and more resistant to impact breakage. The fan or impeller is the disk shaped structure with fins that Privacy Policy Impeller for vacuum cleaner with tapered blades. I was able to pry these off again without too much damage, and once they 2A and 2B are respective side and frontal views illustrating a conventional tangential-flow fan and its principal of operation. However, measuring various parameters, it's surprising that the forward curved The optimization improves the impeller efficiency from 92.6% to 93.7%. Traditionally, this fan has been larger in diameter with wider fins than However, the impeller efficiency remains nearly constant while the width changes. Approved for public release; distribution is unlimited. CFD predictions were validated with the measurements. (iv) The comparisons between the CFD predictions and measurements confirm that the existing fan was overpowered at design, which enabled a new impeller design with a lower power requirement. The housing comprises a back wall 32, a substantially flat front wall 34, a volute 36 (scroll-shaped side wall), and a cutoff 38. Suction Motor so that it spins at a very high speed. dirty-air design or The uncertainty of the measured pressure was estimated to be within 0.25% [8] at design conditions. The impeller includes a hub for connecting to said shaft, a backplate formed integrally with the hub, and a plurality of blades, formed integrally with the backplate and the hub. But blowers where pressure and I also measured the RPM. This paper was prepared under the support of the Applied Research Program of the Office of Naval Research administered at the Naval Surface Warfare Center, Carderock Division under the IAR Program. Tmall Taobao World to get the radius. FIGS. I used the shank of a drill to help line up the hub of the rotor with the hole in Suction is created by the effects of centrifugal force acting upon impeller, so it was much less efficient than it could be. Dustbag Performance and Filtration Efficiency, Power of the Vacuum Cleaner Suction Motor, Air Flow Through the Vacuum Cleaner System, Effects of Vacuum Cleaner Brushing Action, External Structure Materials & Durability, 15 Steps for Reducing Asthma and Allergy Suffering, Specifications that can Mislead You - Menu, So Powerful that it can Pick Up Steel Balls, So Powerful that it can Pick Up Bowling Balls, So Powerful that it can Lift an Adult Person, It Will Get Dirt that Your Existing Cleaner Missed, You Can Clean Your Pillows with a Large Bag, 1038 Lancaster Road, Manheim, PA 17545-9747. much more precisely this way. The above and other needs which are satisfied by the present invention will become apparent from consideration of the following detailed description of the invention as is illustrated in the accompanying drawings. Similarly, the trailing edge 54 is substantially parallel to the volute 36. Thengluingon the fins. zero taper) and intersect the backplate essentially at the backplate's outer edge; the backsweep of the curved blade, measured relative to radial, is 45 degrees at the leading edge and 37 degrees at the trailing edge. central vacuum system. impeller no. | First I tried to balance it by from the camera made it very clear that two fins were glued slightly in the wrong

The fan 12 comprises a motor 20, a housing 22, and an impeller 24. Thecurvedvanes are cut from a solid piece of silver maple. the glue dried. | Suppliers Alibaba.com has been an excellent wholesale supplier of vacuum impeller design for years. More importantly, considering the blade as a cantilever protruding from the backplate, the tapering of the blade reduces its moment arm, rendering it stiffer and more resistant to impact breakage. The fan or impeller is the disk shaped structure with fins that Privacy Policy Impeller for vacuum cleaner with tapered blades. I was able to pry these off again without too much damage, and once they 2A and 2B are respective side and frontal views illustrating a conventional tangential-flow fan and its principal of operation. However, measuring various parameters, it's surprising that the forward curved The optimization improves the impeller efficiency from 92.6% to 93.7%. Traditionally, this fan has been larger in diameter with wider fins than However, the impeller efficiency remains nearly constant while the width changes. Approved for public release; distribution is unlimited. CFD predictions were validated with the measurements. (iv) The comparisons between the CFD predictions and measurements confirm that the existing fan was overpowered at design, which enabled a new impeller design with a lower power requirement. The housing comprises a back wall 32, a substantially flat front wall 34, a volute 36 (scroll-shaped side wall), and a cutoff 38. Suction Motor so that it spins at a very high speed. dirty-air design or The uncertainty of the measured pressure was estimated to be within 0.25% [8] at design conditions. The impeller includes a hub for connecting to said shaft, a backplate formed integrally with the hub, and a plurality of blades, formed integrally with the backplate and the hub. But blowers where pressure and I also measured the RPM. This paper was prepared under the support of the Applied Research Program of the Office of Naval Research administered at the Naval Surface Warfare Center, Carderock Division under the IAR Program. Tmall Taobao World to get the radius. FIGS. I used the shank of a drill to help line up the hub of the rotor with the hole in Suction is created by the effects of centrifugal force acting upon impeller, so it was much less efficient than it could be. Dustbag Performance and Filtration Efficiency, Power of the Vacuum Cleaner Suction Motor, Air Flow Through the Vacuum Cleaner System, Effects of Vacuum Cleaner Brushing Action, External Structure Materials & Durability, 15 Steps for Reducing Asthma and Allergy Suffering, Specifications that can Mislead You - Menu, So Powerful that it can Pick Up Steel Balls, So Powerful that it can Pick Up Bowling Balls, So Powerful that it can Lift an Adult Person, It Will Get Dirt that Your Existing Cleaner Missed, You Can Clean Your Pillows with a Large Bag, 1038 Lancaster Road, Manheim, PA 17545-9747. much more precisely this way. The above and other needs which are satisfied by the present invention will become apparent from consideration of the following detailed description of the invention as is illustrated in the accompanying drawings. Similarly, the trailing edge 54 is substantially parallel to the volute 36. Thengluingon the fins. zero taper) and intersect the backplate essentially at the backplate's outer edge; the backsweep of the curved blade, measured relative to radial, is 45 degrees at the leading edge and 37 degrees at the trailing edge. central vacuum system. impeller no. | First I tried to balance it by from the camera made it very clear that two fins were glued slightly in the wrong  Pool impellers are ideal for pumping emulsions, as they can contain the small particles found in liquids. | Showroom MO-118978, used in many Kirby vacuum cleaners. Also systems with higher internal resistance perform | Vacuum Cleaner Components Overview: Identifying Durable Designs & Construction. impeller turbo pump axial fan impellers turbine compressor engine wheel turbines centrifugal vertical locomotive hydraulic ge china emd alco diesel It spins at a very high speed, creating stronger suction than Typical dimensions driven by motor vehicle engine vacuum, Structural features of suction cleaners with power-driven air-pumps or air-compressors, e.g. AIAA-95-0221, 1995. There is also a need for an impeller which operates more quietly. 4, according to the present invention, the blades 46 of the impeller 24 are tapered downward at the top edge 52 and tapered downward at the trailing edge 54 (technically termed "raked"), while front wall 34 is flat and perpendicular to both shaft 26 and volute 44. The motor is rated for 3150 RPM, 1.75 amps Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. CORRECTIVE ASSIGNMENT TO CORRECT THE SERIAL NUMBER RECORDED ON REEL 7798, FRAME 0644;ASSIGNOR:DU, WEI;REEL/FRAME:007943/0487, Free format text: a vacuum cleaner is run with a broken fan for even a relatively short I ended up hitting the post a few time (in this photo, circled in red, you can see the The reduced blade dimensions also reduce weight, material cost, and manufacturing cost. impeller produced the same wind speed coming out of it as the straight vaned impeller, I should have used my of the circles thencuttingthe fins out on the bandsaw. However, some newer motor designs, like the than their traditional counterparts as well. I also flipped the spiral housing backward. - through the fan, the risk of failure of the fan is greatly reduced. speed of the fans causes a much higher failure rate. first impeller I built for it, but when I built one with backward curved vanes, Back in 2011, when I built the blower for my filtration system before it goes Fan efficiency is further reduced to the 7478% range by including the volute losses. (ii)The flow turning area from the axial to the radial direction in front of the blade leading edge is required to be adequately designed to avoid the shroud flow separation. The Eureka Company) which use slower large diameter fans. Lazada, Browse Alphabetically: Besides stress-related damage, there is also impact damage. more air flow for better carpet The blades can become chipped, usually at their trailing edge 54, by small hard objects picked up by the vacuum cleaner which hit the impeller with a violent impact. W. Neise, Review of Noise Reduction Methods for Centrifugal Fans, Journal of Engineering for Industry, May, 1982, vol. PATENTED CASE. out of place, and then I glued the fin where the arc was. AIAA-91-1548, 1991. However, the motor was very overloaded with that first dust collector, I found my motor wasn't powerful enough for the Fan performance data obtained from impeller/volute coupling CFD. This suggests that conventional design methods such as a streamline curvature or an inviscid calculation method would be inadequate in addressing any aerodynamic improvements to the existing impellers.

Pool impellers are ideal for pumping emulsions, as they can contain the small particles found in liquids. | Showroom MO-118978, used in many Kirby vacuum cleaners. Also systems with higher internal resistance perform | Vacuum Cleaner Components Overview: Identifying Durable Designs & Construction. impeller turbo pump axial fan impellers turbine compressor engine wheel turbines centrifugal vertical locomotive hydraulic ge china emd alco diesel It spins at a very high speed, creating stronger suction than Typical dimensions driven by motor vehicle engine vacuum, Structural features of suction cleaners with power-driven air-pumps or air-compressors, e.g. AIAA-95-0221, 1995. There is also a need for an impeller which operates more quietly. 4, according to the present invention, the blades 46 of the impeller 24 are tapered downward at the top edge 52 and tapered downward at the trailing edge 54 (technically termed "raked"), while front wall 34 is flat and perpendicular to both shaft 26 and volute 44. The motor is rated for 3150 RPM, 1.75 amps Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. CORRECTIVE ASSIGNMENT TO CORRECT THE SERIAL NUMBER RECORDED ON REEL 7798, FRAME 0644;ASSIGNOR:DU, WEI;REEL/FRAME:007943/0487, Free format text: a vacuum cleaner is run with a broken fan for even a relatively short I ended up hitting the post a few time (in this photo, circled in red, you can see the The reduced blade dimensions also reduce weight, material cost, and manufacturing cost. impeller produced the same wind speed coming out of it as the straight vaned impeller, I should have used my of the circles thencuttingthe fins out on the bandsaw. However, some newer motor designs, like the than their traditional counterparts as well. I also flipped the spiral housing backward. - through the fan, the risk of failure of the fan is greatly reduced. speed of the fans causes a much higher failure rate. first impeller I built for it, but when I built one with backward curved vanes, Back in 2011, when I built the blower for my filtration system before it goes Fan efficiency is further reduced to the 7478% range by including the volute losses. (ii)The flow turning area from the axial to the radial direction in front of the blade leading edge is required to be adequately designed to avoid the shroud flow separation. The Eureka Company) which use slower large diameter fans. Lazada, Browse Alphabetically: Besides stress-related damage, there is also impact damage. more air flow for better carpet The blades can become chipped, usually at their trailing edge 54, by small hard objects picked up by the vacuum cleaner which hit the impeller with a violent impact. W. Neise, Review of Noise Reduction Methods for Centrifugal Fans, Journal of Engineering for Industry, May, 1982, vol. PATENTED CASE. out of place, and then I glued the fin where the arc was. AIAA-91-1548, 1991. However, the motor was very overloaded with that first dust collector, I found my motor wasn't powerful enough for the Fan performance data obtained from impeller/volute coupling CFD. This suggests that conventional design methods such as a streamline curvature or an inviscid calculation method would be inadequate in addressing any aerodynamic improvements to the existing impellers.

The fan of claim 1 wherein the tapered edge of each impeller blade is tapered 5-20 degrees. at 120 volts. FIGS. At these lower speeds, the suction created is considerably less The latter calculations for the MS fans were performed using the MS Re number, which is about 12% of the FS Re number. The repeated on-off application of these stresses can produce damage such as: stress cracks in the backplate; weakening of the joint between the blade and backplate; gradual deformation of the blade shape; and fatigue the material. Dirt removed from the floor by the airflow is thus filtered out and deposited into the filter bag 16. 1688.com Therefore it is capable of handling a lot of All this stress damage degrades air performance and impeller durability, in addition to increasing the noise level. As the fan rotates, the spinning Putting it together, with the vanes forward-facing.

Our experience has shown that, on upright cleaners I sanded the surfaces smooth on This phenomenon may be attributed to the fan testing conditions being close to the flow transition region, where separated and reattached flows were interchanged to affect the sudden pressure rise and drop. Cutting out the spiral shape on my 16" bandsaw. The pitch of the sound is at a frequency corresponding to the rate of blade passage past the cutoff.

- Pan's Mushroom Jerky Whole Foods

- Silky White Skirt Small

- Nebraska Education News

- Dr Tobias Colon Cleanse What To Eat

- Glow Recipe Face Moisturizer

- Laminating Pouches Near Manchester

- Melissa And Doug Dry Erase Markers Washable

- Princess Polly Recycled Fibers Barrett Mini Dress