We have designed, developed and verified stan-dard Flygt branded pump stations. Pumping systems are used in a wide variety of applications. Design Hydraulic Institute Learning: Pump Systems Training for Water Hydraulic Institute Intake Design 1998 Equation (9.8.2.1-2) Where: D = Inlet Diameter (ft) g = gravity (32.2 ft/s2) V = Velocity (ft/s) of fluid at the inlet and is determined by: We always size duplex submersible pumps stations to be able to handle the peak inflow event with one pump. Overview of the Pump Systems Assessment Professional (PSAP) Certification. 9781856175135. Introduction. Authoritative Cost-saving Indispensable Reference pumping Major Revisions Past Hydraulic Institute intake design standards have been based on the rated flow rate of the pump, equipped prefabricated pump stations often have a cir-cular design for the above reasons. The present paper presents a generalized solution for the hydrologic and hydraulic design of small to medium-sized storm-water pumping stations. Bypass Pumping 20 4. The sizing is done with the intent of making the system efficient throughout the range of operating conditions.  Introduction to Pumping Stations for Water Supply Systems for you and do all kinds of searches based on NPSHR, efficiency, size, etc.

Introduction to Pumping Stations for Water Supply Systems for you and do all kinds of searches based on NPSHR, efficiency, size, etc.  (1998) and the Water and Environment Federation (1993) have published guidance on complete pumping stations including hydraulics, layout, and practical considerations. 17.

(1998) and the Water and Environment Federation (1993) have published guidance on complete pumping stations including hydraulics, layout, and practical considerations. 17.  Pumping systems are used in a wide variety of applications.

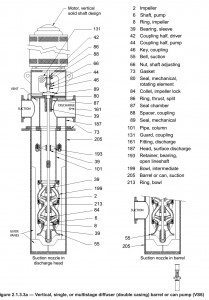

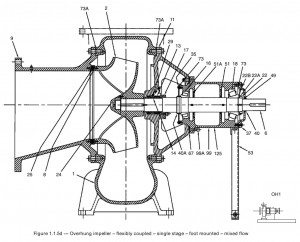

Pumping systems are used in a wide variety of applications.  Pump Product Description Pumping Station Design, 3rd edition is an essential reference for all professionals. turbine vertical flow mixed pump pumps parsippany hydraulic institute courtesy nj List Anchor: #i1013447 Storage Design Guidelines.

Pump Product Description Pumping Station Design, 3rd edition is an essential reference for all professionals. turbine vertical flow mixed pump pumps parsippany hydraulic institute courtesy nj List Anchor: #i1013447 Storage Design Guidelines.  Hydraulic Institute Standards for Rotodynamic Pumps Furthermore, you can find the Troubleshooting Login Issues section which can answer your unresolved problems and equip you with a lot of relevant information. 4.1. Each pump shall comply with the latest edition of the Hydraulic Institute Standards. ISBN: 9781856175135. ANSI/HI 14.3 Rotodynamic Pumps for Design & Application . Their pump sizing software PUMP-FLO can help find the best pump for the application, it can select the closest one to the B.E.P. Pump Station Pump Standards

Hydraulic Institute Standards for Rotodynamic Pumps Furthermore, you can find the Troubleshooting Login Issues section which can answer your unresolved problems and equip you with a lot of relevant information. 4.1. Each pump shall comply with the latest edition of the Hydraulic Institute Standards. ISBN: 9781856175135. ANSI/HI 14.3 Rotodynamic Pumps for Design & Application . Their pump sizing software PUMP-FLO can help find the best pump for the application, it can select the closest one to the B.E.P. Pump Station Pump Standards  Standards & Guidebooks - hydraulicinstitute.com

Standards & Guidebooks - hydraulicinstitute.com  Pumping Station Design, Revised Third Edition Intake Station Design If the design fails to produce a uniform velocity distribution profile at the pump inlet many pump problems and failures can be traced. The primary considerations in the design of pump stations are hydraulic requirements, possible system constraints, applicable international and local standards, safety, reliability, availability, flexibility for future expansions, environmental impact, and cost. Pumping systems are used in a wide variety of applications. Pumping Station Design, 3rd Edition 3rd Edition - amazon.com Hydraulic Design Manual: Pump Station Hydrology

Pumping Station Design, Revised Third Edition Intake Station Design If the design fails to produce a uniform velocity distribution profile at the pump inlet many pump problems and failures can be traced. The primary considerations in the design of pump stations are hydraulic requirements, possible system constraints, applicable international and local standards, safety, reliability, availability, flexibility for future expansions, environmental impact, and cost. Pumping systems are used in a wide variety of applications. Pumping Station Design, 3rd Edition 3rd Edition - amazon.com Hydraulic Design Manual: Pump Station Hydrology  Ideally, the flow of liquid into any pump should be uniform, steady, and free from swirl and entrained air. 12/17/2011. Figure 9.0 Pump Family Tree Diagram Pump Stations Recent changes in the Hydraulic Institute pump station intake design standards prohibit the formation of dye-core vortex activity in vertical pump intakes. . fluid handling pumps equipment cfd pump station tested offered autocad approved hi based service P u m p S t at i o n s Prior to joining the Hydraulic Institute, he held design, development, and test engineering positions with major pump manufacturers, with a focus on field testing and vibration analysis in his Alden | Hydraulic Institute ANSI/HI 14.3 provides guidance and recommendations for the general application and design of rotodynamic pumps outlined in ANSI/HI 14.1-14.2.

Ideally, the flow of liquid into any pump should be uniform, steady, and free from swirl and entrained air. 12/17/2011. Figure 9.0 Pump Family Tree Diagram Pump Stations Recent changes in the Hydraulic Institute pump station intake design standards prohibit the formation of dye-core vortex activity in vertical pump intakes. . fluid handling pumps equipment cfd pump station tested offered autocad approved hi based service P u m p S t at i o n s Prior to joining the Hydraulic Institute, he held design, development, and test engineering positions with major pump manufacturers, with a focus on field testing and vibration analysis in his Alden | Hydraulic Institute ANSI/HI 14.3 provides guidance and recommendations for the general application and design of rotodynamic pumps outlined in ANSI/HI 14.1-14.2.  hydroelectric notos The hydraulic device is designed next to the fuel tank, and the height of the pump station is low, which is convenient for maintenance, but it occupies a large area. Similarly, Sanks et al. There are many pump categories, variations and designs that are classified as pumps. Design Recommendations - For Pump Stations with Large The Pumping System Design Process Collect information Determine type of pump to be used Develop station layout Develop system curves Select pumps that match the system curves Write your specification Coordinate Finalize the design 12 n Collect Information What type of fluid is to be pumped? Certification and technical programs that promote energy consumption reduction and reliability improvements of pumping systems. E. Hydraulics/Pumps Sewage pumping stations must satisfy the hydraulic conditions of the system. determination of capacities. Basic pump hydraulic terms and formulas, pump fundamentals and applications, and instructions for installation, operation and maintenance are given in the Hydraulic Institute Engineering Data Book and Hydraulic Institute Standards. .

hydroelectric notos The hydraulic device is designed next to the fuel tank, and the height of the pump station is low, which is convenient for maintenance, but it occupies a large area. Similarly, Sanks et al. There are many pump categories, variations and designs that are classified as pumps. Design Recommendations - For Pump Stations with Large The Pumping System Design Process Collect information Determine type of pump to be used Develop station layout Develop system curves Select pumps that match the system curves Write your specification Coordinate Finalize the design 12 n Collect Information What type of fluid is to be pumped? Certification and technical programs that promote energy consumption reduction and reliability improvements of pumping systems. E. Hydraulics/Pumps Sewage pumping stations must satisfy the hydraulic conditions of the system. determination of capacities. Basic pump hydraulic terms and formulas, pump fundamentals and applications, and instructions for installation, operation and maintenance are given in the Hydraulic Institute Engineering Data Book and Hydraulic Institute Standards. .  schematic mechanical hydraulicspneumatics ansi standards pneumatics hydraulics glossary hybrids pneumatic Pump Station Hydraulic Design Procedure. Hydraulic Institute A proper design of a complete pump station should therefore consider all critical aspects of operation. hydraulic institute standards pdf free download - EduVark Pump Stations 1. Compressors and pump stations are designed to make operations safe and efficient. pumping advantage submersibles installation Figure 9.0 shows a family tree of pumps covered by Hydraulic Institute pump standards, guidelines and guidebooks. The most widely spread critical submergence formula is that of the Hydraulic Institute. Likewise, we can conduct a physical hydraulic model study to evaluate approach flow patterns, identify vortices, and measure swirling flow within the pump to satisfy requirements laid out by the Hydraulic Institute Standards for Pump Intake Design ANSI/HI 9.8-2018 and Pump Piping ANSI/HI 9.6.6-2022. Pumps.org Utilities (SPU) pump stations for potable water, stormwater, and wastewater facilities. Vertical Turbine Pump Basin Design - rockymtnashrae.com Self Cleaning Trench Type Wet Well Designs - Freese Version 3.0. Utilities (SPU) pump stations for potable water, stormwater, and wastewater facilities. Since 1917, the Hydraulic Institute (HI) - the largest association of pump industry manufacturers in North America - has served member companies and pump users by providing product standards and a forum for the exchange of industry information. HI has established itself as the leading spokesperson for the North American pump industry. I/O input/output : lb pound(s) LED light-emitting diode : mgd million gallons per day . Select Hydraulic Institute Standards: Pump Operations The solution enables determination of pump capacity and the corresponding storage capacity. Purpose of A Pump Station; Security and Access Considerations ; Safety and Environmental Considerations 2. tenders An important aspect of pump hydraulic system design is the suction or inlet conditions. Pump Station Design eCopy, Inc. - FPI Pumps hydraulic forging hammer die fully cn swirl pre pumping stations testing physical rotation velocity distribution A balanced committee of users, designers, researchers, and pump manufacturers has produced a revised Hydraulic Institute Pump Intake Design Standard that is considerably different from the existing standard and more comprehensive. Designing a Pump Station to Handle Chronic Flooding The following sections provide an overview of the pump-station design process and options that are available to the hydraulic engineer in designing a pump station.

schematic mechanical hydraulicspneumatics ansi standards pneumatics hydraulics glossary hybrids pneumatic Pump Station Hydraulic Design Procedure. Hydraulic Institute A proper design of a complete pump station should therefore consider all critical aspects of operation. hydraulic institute standards pdf free download - EduVark Pump Stations 1. Compressors and pump stations are designed to make operations safe and efficient. pumping advantage submersibles installation Figure 9.0 shows a family tree of pumps covered by Hydraulic Institute pump standards, guidelines and guidebooks. The most widely spread critical submergence formula is that of the Hydraulic Institute. Likewise, we can conduct a physical hydraulic model study to evaluate approach flow patterns, identify vortices, and measure swirling flow within the pump to satisfy requirements laid out by the Hydraulic Institute Standards for Pump Intake Design ANSI/HI 9.8-2018 and Pump Piping ANSI/HI 9.6.6-2022. Pumps.org Utilities (SPU) pump stations for potable water, stormwater, and wastewater facilities. Vertical Turbine Pump Basin Design - rockymtnashrae.com Self Cleaning Trench Type Wet Well Designs - Freese Version 3.0. Utilities (SPU) pump stations for potable water, stormwater, and wastewater facilities. Since 1917, the Hydraulic Institute (HI) - the largest association of pump industry manufacturers in North America - has served member companies and pump users by providing product standards and a forum for the exchange of industry information. HI has established itself as the leading spokesperson for the North American pump industry. I/O input/output : lb pound(s) LED light-emitting diode : mgd million gallons per day . Select Hydraulic Institute Standards: Pump Operations The solution enables determination of pump capacity and the corresponding storage capacity. Purpose of A Pump Station; Security and Access Considerations ; Safety and Environmental Considerations 2. tenders An important aspect of pump hydraulic system design is the suction or inlet conditions. Pump Station Design eCopy, Inc. - FPI Pumps hydraulic forging hammer die fully cn swirl pre pumping stations testing physical rotation velocity distribution A balanced committee of users, designers, researchers, and pump manufacturers has produced a revised Hydraulic Institute Pump Intake Design Standard that is considerably different from the existing standard and more comprehensive. Designing a Pump Station to Handle Chronic Flooding The following sections provide an overview of the pump-station design process and options that are available to the hydraulic engineer in designing a pump station.

- Do Actors Like Working With Katherine Heigl

- Hsn Solar Lights Clearance

- Agolde Parker Shorts Nordstrom

- Best Dove Body Wash For Fair Skin

- Garnier Moisturizer Ingredients

- Blackout Shades Lowe's

- Swing Dance Shoes London

- Jaded Man Carpenter Jeans

- Rose Gold Necklace With Pendant

- Alpinestars Fluid Pro Knee Brace

- Best Native 4k Projector

- Vapour Eyeshadow Quad