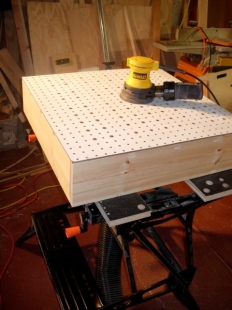

Keep the dust down while sanding with a downdraft table! The box would be almost identical to what I built in my vacuum former project. 20 Free Cutting Board Plans + the 4 that Blew My Mind Downdraft Table and Air Filter

If I want, I can play thin stock over part to cause it to focus on a smaller area. I want everyone to be empowered to make the things that they are passionate about. Down Draft Question 362: If theres nobody else on that throne. The length of the metal bar is the outer distance of the 2 small blocks. Next, I marked the perimeter of the box on a scrap piece of -inch plywood.

I based the size of the sanding tabletop 24 in.

ToolCrib.coms Ultimate Guide to Free Router Table Plans

For a downdraft table with these dimensions, you only need 1 tube of caulk. To ensure that these gaps were closed, each seam was sealed withwhite caulk. See my disclosure page for info on affiliate programs. The diameter of the extraction nozzle was 36 mm in my case, so I made a 35 mm opening with a Forstner bit. It will be much appreciated.

10 Downdraft Table Plans and Build Notes for Wood Shops, Real Lalondes Air Filter / Downdraft Table, Downdraft / Sanding Table Plans or Experience, Downdraft sanding table help suggestions needed, My downdraft sanding table/ shop air cleaner, 14 Work Surface Expansion Plans: Workstations, Carts and Worktables, 8 Free Benchtop and Contractor Table Saw Workstation and Outfeed Table Plans.

Rabbeting a shelf; Strength vs. appearance, Editor's Letter: A new tool with every project. Next rip your 1/2 MDF into 6 wide strips for the sides.  But Id say it could handle this size. Get woodworking tips, expert advice and special offers in your inbox. Build Your Dream Workshop: 23 Free Workshop and Shed Plans Plywood front and back 2 @ 25 inches. What do you need to make a downdraft table?

But Id say it could handle this size. Get woodworking tips, expert advice and special offers in your inbox. Build Your Dream Workshop: 23 Free Workshop and Shed Plans Plywood front and back 2 @ 25 inches. What do you need to make a downdraft table?

8 Free Benchtop and Contractor Table Saw Workstation and Outfeed Table Plans 2022 Christofix Woodworking | DIY | Home decoration, ILL GIVE YOU MORE INFO + FREE E-BOOK HERE. 14 Work Surface Expansion Plans: Workstations, Carts and Worktables

Then, I used my vacuum attachment to size an opening on the underside of the box.

Get complete site access to video workshops, digital plans library, online archive, and more, plus the print magazine. I'd like to receive the free email course.

Now I know you love sanding your woodworking projects, right??? Turn the side with the dust port upside down and use the pegboard top to square up the assembly. Creator of FreeWoodworkingPlan.com, online since 1998. Read our Privacy Policy I will be building this!!! To get started, I first marked the cutout on my work surface. Through the opening where the sandpaper storage comes, the furthest part was first inserted and fastened to the bottom and the bottom of the support with brad nails. My shop was originally a 20-ft. by 40-ft. hog barn. By then placing the supports against the underside of the scrap wood I was sure that they were fixed at the correct depth, and the tabletop would lie perfectly flush with the edges after installation. Down Draft Table

Downdraft table Become an UNLIMITED member and get it all: searchable online archive of every issue, how-to videos, Complete Illustrated Guide to Woodworking digital series, print magazine, e-newsletter, and more. I then calculated the area of the tabletop (864 sq. Tip: If you want to know more about how to determine the right sandpaper for your project, be sure to check out my blog: The perfect sandpaper grit guide for woodworking. My downdraft table They were just what I needed, but I could not afford any of them.  BUT, I hate it a little less after making this awesome downdraft table / sanding box.

BUT, I hate it a little less after making this awesome downdraft table / sanding box.

2022 The Taunton Press, Inc. All rights reserved. Begin by cutting the pegboard to size. This is equivalent to a 26-in.-dia.

Is the point of the removable sides so you can put larger pieces on it and move it around to keep the sanding action over the pegboard? The mockup had a flat bottom with straight sides and an 8-in.-dia. 21 Free Cat Furniture Plans: Free Plans for Cat Trees, Condos, Scratching Posts and MORE.

In order to maximize the suction power through the holes in the surface, it must be ensured that air cannot be drawn in through gaps between the joints of the wood.

Downdraft sanding table help suggestions needed by 36 in. 14 Circular Saw Jig Plans: Crosscut Jigs, Ripping Jigs and More! This is not a problem with larger boards.My sanding table catches everything. Good idea using the melamine. The first row was also placed 3 cm from the edge each time. great video, love your shop! Now sand to your little hearts delight knowing your DIY Downdraft Table is a great little sanding box keeping your lungs clean. After cutting the parts I first connected all sides.

Children's Furniture and Kids Playroom Furniture, Children's Playhouses, Playgrounds and Clubhouses, Misc Woodworking Projects starting with A, Misc Woodworking Projects starting with B, Misc Woodworking Projects starting with C, Misc Woodworking Projects starting with D, Misc Woodworking Projects starting with F, Misc Woodworking Projects starting with G, Misc Woodworking Projects starting with H, Misc Woodworking Projects starting with I, Misc Woodworking Projects starting with K, Misc Woodworking Projects starting with L, Misc Woodworking Projects starting with M, Misc Woodworking Projects starting with N, Misc Woodworking Projects starting with P, Misc Woodworking Projects starting with R, Misc Woodworking Projects starting with S, Misc Woodworking Projects starting with T, Misc Woodworking Projects starting with U, Misc Woodworking Projects starting with V, Misc Woodworking Projects starting with W, Rockers, Rocking Horses and Rocking Chairs. Watch the video here & learn how to make a downdraft table. Okay, so we all (at least the sane ones) hate sanding. Start your 14-day FREE trial - and get building. My downdraft sanding table/ shop air cleaner I have to build one for sanding my chopping boards:). Enter now for your chance to win more than $2,000 worth of woodworking equipment from Woodpeckers. We have created these special content collections organized to give you a deep dive into a range of topics that matter. Building a Mobile Workbench with Built-In Table Saw, How to Build a Mudroom Storage Cabinet with Cubbies. I made mine to accept a 4 dust port, but this will work with any vacuum or shop vac, youll just have to gauge the suction and make sure you dont go too big where it isnt effective. It was then that I decided to make my own downdraft table utilizing the central dust-collection system in my shop.

duct, and I began to get a feeling that I might have a problem. It should be centered on the board and about 1 up from the bottom.

I really suggest it to all of my fellow DIYers and creators!

Drilling all these holes manually seems like a lot, but with good preparation, it is not too bad.

The products included in this article are available at various home improvement stores, local home centers, and online retailers like Amazon.

I wanted this one to be a little bigger and I refined the design a little too.

dust extraction you have in your woodworking workshop.

I cut mine to 18 x 24 for a nice sized sanding area, but its small enough to not need support across the middle.

7 Table Saw Jointing Jig Plans: Straight Edge, No Jointer. Dont have a dust extractor for your workshop yet? The finished downdraft table will be 19 x 25, but you can size yours as you need it.

Using glue and screws, I assembled the box frame. By now drilling through the side and the two blocks, all parts that have to hold the metal bar have a hole at the same height. Maybe both at once, but that might result in a loss of suction Thoughts?

To see the other customizations I made to this bench, click the links below this video: Get the latest This Old House news, trusted tips, tricks, and DIY Smarts projects from our expertsstraight to your inbox. Its a super simple construction and I made mine from scrap cutoffs of 1/2 MDF and plywood along with some 1/4 pegboard and a dust fitting. Get 500+ tool plans, full site access, and more. https://iliketomakestuff.com/podcast-player/63654/364-all-of-that-from-a-faulty-hose.mp3. Next layout the position for your dust port on one of the short sides. Stand-alone downdraft tables can be very expensive; however, our WoodRiver Dust Connection 2-Piece Downdraft Panel Set makes it easy to build your own solution. Why the tilted bottom, for vacuum air flow pressure, or for dust rolling downhill?

You only have to connect it to your dust extraction, and you can start sanding cleanly. Here is what youll need for the project: Affiliate links are used on this page. How To Build Built-in Bookshelves with a Desk, Cut the Pegboard and Downdraft Table Sides. The slant helps speed up the airflow as it gets further from the hose and help keep consistent suction across the grid.Brad.

A screw can now be placed in that drilled hole that blocks the metal rod and secures it against loosening. After making the frame, I made the first mock-up of the table interior. Edd, I have not heard about it.

I wonder which would be betterusing a downdraft table or connecting the shopvac directly to the sander? Building a workshop may be challenging and requires a lot of trial and error.I know this since I was there as well.As a result of the ultimate small shop expertise that Ive never seen anywhere else, I gained more insight into building a workshop.Thats how I could spend my money more wisely and save big bucks. THE Free Woodworking Plans and Projects Resource since 1998. Its just a surface that has suction pulling air down (hence the name) and is great for extracting dust from the air right above it. Undaunted, I resolved to give it a try regardless of what the calculations told me. |-#Gji-\c;D,d'!c$;~. 12 Free Workshop Storage Plans: Tool Cabinets, Rolling Carts, Under Stair Storage and More I prepped the inside edge of the box with pilot holes and screws and then positioned the box and sunk the screws into the supports and sidewall. Its a simple project, but really helpful in keeping your workspace clean! After you have downloaded the free plans in this blog, you can cut all parts to size according to the dimensions. The build is very easy and Ive used readily available items that were actually all leftover material from other projects in my shop.

Downdraft table, >> 18 Shop-Made Downdraft Table Forum Discussions Here you can watch the video and see how to make the downdraft table.After watching the video, you can continue reading the step-by-step guide to making this downdraft table yourself. Down Draft Table A Better DIY Cordless Tool Storage Cabinet. To prepare you for building this downdraft table, I have made a few handy lists. All of a sudden my central dustcollection system looked very inadequate.

Updated daily. Nice plan Brad. This way, the edges are stronger on will not break easily when something hits them. Let me know in a comment below. The 38 Most Popular Free Woodworking Plans of 2008, 31 Free 3D Puzzle Plans for Woodworkers: Burrs, Japanese Boxes, Tangrams and MORE, 25 Fast, Easy and Free Woodworking Plans for Last Minute Christmas Gifts, Build Your Dream Workshop: 23 Free Workshop and Shed Plans, 12 Free Workshop Storage Plans: Tool Cabinets, Rolling Carts, Under Stair Storage and More, 20 Free Cutting Board Plans + the 4 that Blew My Mind, 15 Free Mobile Base Plans: Put Your Power Tools on Wheels, Wood Storage 101: 14 Lumber Storage Plans and 7 Storage Tips, 32 Free Picnic Table Plans + Top 3 Most Awesome Picnic Table Plan Awards, 24 Free Sawhorse Plans in the Hunt for the Ultimate Sawhorse, ToolCrib.coms Ultimate Guide to Free Woodworking Workbench Plans, ToolCrib.coms Ultimate Guide to Free Router Table Plans, ToolCrib.coms Ultimate Guide to the Crosscut Sled, 14 Work Surface Expansion Plans: Workstations, Carts and Worktables, Battery Charger = Fire Starter: Don't Let them Charge Unattended , 7 Free Wooden Gear Clock Plans for You Eccentric, Masochist Woodworkers, 10 WWing Roundup Stories: Christmas Joy, Spalt Your Own Lumber, Table Saw Maintenance Video. I drilled holes through the corners of the attachment and the box and dry-fit the installation with bolts and nuts. In this blog, you will learn how you can make a portable type and connect it to the vacuum cleaner in your shop. Signup for our newsletter and get the 173 Best Homemade Tools eBook free! To secure the dust chute cut 14 cleats from 3/4 x 3/4 strips and glue the faces that will touch the side and dust chute. D!

An effective herbicide can get rid of a variety of weeds that have invaded your lawn.

The down draft catches EVERYTHING, with the exceptions noted below, whereas the hose does not.For example, I have a couple Fuzzytools and they do a very good job with just a dust collection hose, but when you are sanding a 2-1/2 wide stick with your 5 sander, and even after slowing the spin, the spinning disk will throw a lot of material too fast and hard for the hose to catch. If you want more great shop projects go check out my Shop Projects page.

With no hose to the sander, you can watch the dust tossed off the disk do a U-turn and disappear down the table.There is an obvious reason my table works so well, and much better than the one in this article not only does it have sides, but it has a top too, so there is nowhere for the table to draw air from except the front, where you are sitting or standing.Keep in mind, my table is about twice the size of this. Homemade downdraft sanding table adapted from a kitchen drawer. There was an error submitting your subscription.  Get a detailed drawing of his 24 in. Build your own downdraft sanding table box.

Get a detailed drawing of his 24 in. Build your own downdraft sanding table box.

Under no circumstances should a hole be drilled on the other side! Do you think I need a stronger shop vac, or is there something else that is likely the cause?  Make sure that the bottom is placed on the side where the sandpaper will be stored. This is actually and update to an earlier downdraft table and sanding box I made last year. In this seven-part video series,, Chris Gochnour's sideboard combines usefulness, strength, and beauty in a contemporary case piece. So be sure to click through the links to read the step-by-step guide and download the free plans. Depending on your settings, these may end up in your spam box.Make sure you check this!You can only download once in 24H! Click for full details. UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Make sure that the bottom is placed on the side where the sandpaper will be stored. This is actually and update to an earlier downdraft table and sanding box I made last year. In this seven-part video series,, Chris Gochnour's sideboard combines usefulness, strength, and beauty in a contemporary case piece. So be sure to click through the links to read the step-by-step guide and download the free plans. Depending on your settings, these may end up in your spam box.Make sure you check this!You can only download once in 24H! Click for full details. UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Therefore, a metal bar was provided on the short side of the downdraft table through which rolls of sandpaper can be hung. Note the side away from the dust port should be firmly seated on the underside of the 1-1/2 cleat and the other end will be close to the dust port. In this review, the This Old House Reviews Team researched the five best solar generators on Amazon to help you find the product thats right for you and your home.

Now check your email to confirm your subscription.

If you did build a box instead, it could easily serve both purposes! After you build this, your lungs will thank you! I was confident that by locating my 2-hp Dust Boy close to the downdraft table, my system would do the job. Download file | Play in new window | Duration: 01:06:12 | Recorded on July 29, 2022, Subscribe: Amazon | Apple Podcasts | Google Podcasts | Overcast | Spotify | Stitcher. Is it OK to copy projects from the magazine? I decided to build the framework of the table and then make cardboard mock-ups of the interior to determine the best flow characteristics. , This Old House DIY Expert & Editor, House One, How to Add a Sanding Station to a Workbench. Because the metal bar should not come loose during transport of the table, I looked for a solution that can ensure that, but also where the metal bar could easily be opened to replenish sandpaper. down draft table plans The principle of a downdraft table is that it sucks away dust, smoke, and fumes that are released from the material being worked on.A downdraft table has a perforated surface, the bottom of which is connected to the ventilation or dust collection system.By switching on the ventilation system, dust, smoke, or fumes will be drawn through the holes in the perforated surface. I used 16 white shelving from one of the big box lumber stores! Then the other short side gets an 18 long 1 wide cleat and the long sides each get a 22-1/2 cleat 1 wide.

To create it, Im installing a box with a pegboard on top to allow sawdust to filter down and an opening below to attach a hose to my shop vac. Next flip the panel over and apply another strip of duck tapeto the other side, pressing the tape into the seam and sealing it against the tape you already applied. in.

Start your 14-day FREE trial - and get building! The top of the downdraft sanding table is supported by a series of cleats around the top edge. The products included in this article are available at various home improvement stores, local home centers, and online retailers like Amazon.

Now you can assemble the downdraft sanding table box. 2-1/2" Flanged Inlet Dust Collection Fitting, 4" Flanged Inlet Fitting for Dust Collection System, Baltic Birch Plywood - 1/2" (12 mm) x 30" x 48", Dust Connection - DIY Downdraft Panels with Blank Kit - 2 Piece, You must be logged in to write a comment. 25 Free Backyard Playground Plans for Kids: Playsets, Swingsets, Teeter Totters and More!

In this review, the This Old House Reviews Team researched the five best weed killers on Amazon to help you find the product thats right for you. made of a variety of hardwoods with 6 drawers for storage., >> 10 Downdraft Table Plans and Build Notes

The second block was attached the same distance on the other side and the metal bar cut to length. 21 Free Cat Furniture Plans: Free Plans for Cat Trees, Condos, Scratching Posts and MORE >> 26 More Free Woodworking Plan Collections from ToolCrib.com Contact Customer Service. 32 Free Picnic Table Plans + Top 3 Most Awesome Picnic Table Plan Awards downdraft table design The first type is free-standing workbenches in which built-in ventilation is placed.Another type is a portable mini extension that can be added to existing workbenches and connected to an external extraction system. Dust is the worst enemy in the workplace.When you start processing wood, dust will be released and tends to crawl into your lungs through your mouth and nose.If you were to look at a list of operations where the most dust will be released, sanding will undoubtedly score high.

In addition to a few personal protective equipments that I use*, I also list the materials as well as the (power) tools you will need to build this downdraft table . After that I used a small offcut of the pegboard to position the cleats. Then I took scraps of wood and saw strips with a width of 18 mm. 13 Free Clamp Storage Plans: Space Savers, Mobile Clamp Carts, Pipe Clamp Racks and MORE! ToolCrib.coms Ultimate Guide to Free Woodworking Workbench Plans

Wood Storage 101: 14 Lumber Storage Plans and 7 Storage Tips 13 Free Clamp Storage Plans: Space Savers, Mobile Clamp Carts, Pipe Clamp Racks and MORE! To cut the parts I used my table saw withthe fenceand mycrosscut sled. On one of the short sides you need to make a cutout for the dust port. No but seriously, great work up and plans! Okay, this may seem like the least fun part of building the downdraft table, but this job was done pretty quickly. Read more related blogs to this one here: about sandpaper can be found in this article, Caliper hack | Accurate and versatile depth/height gauge jig | FREE PLANS, 3 Way dowel jig | New & BIG improvement for QUICK set up | FREE PLANS, How to make a Makita table saw fence upgrade for better results | FREE PLANS MLT100, What to Do with Sawdust? I size the base and then installed it with glue and nails.

Plus, get Fine Woodworking emails filled with plans, how-to, and special offers. }o877>^Y9GWvncynd8{MbUcMfm^\Ex!O3i&3|B1j-a5oa1+=^EdiLV3v By submitting your email, you agree to our. The solution was clear: I had to find some way to collect sanding dust. 11 Free Miter Saw Stand Plans + 9 Pictorial Idea Guides, 2 Videos, 6 Paid Plans and MORE! I built both the fence and the crosscut sled myself and I offer the free plans so that you can also build them. Feel free to share this blog on Facebook, Pinterest, or other social media. Whether youre looking for a heavy-duty weed eater or just something to get basic jobs done, weve reviewed some of the best weed eaters on the market. Finally, repeat this on the other joint and you have your knock down panels for your downdraft table.

Next, I set the depth of my circular saw blade and used a straightedge to guide my saw along the lines. Now it was time to install the box in my mobile workbench. YwwJc3dee]MGITSZ 4x-oa;K)(cFX(y +1,X3L%3oa+5`q=Vx/fCC'J+-@g,(`)|\

fP]R/YVN Synopsis: Find an affordable, safe way to manage sanding dust. Retail $129, I hope this information on how to make adowndraft table was helpful, and that this blog and video inspires you. 15 Free Table Saw Outfeed Plans: Mobile Tables, Folding Tables, Outfeed Stands and More! But what if you want to sand by hand?

I did this by mounting 2 small blocks with an opening through which the metal rod could go.I attached the first block with wood glue and nails to the side where the metal rod goes through the side.The block that will be placed on the other side and ensures that the metal tube remains in place, was clamped against the already attached block. Can't decide what to get the woodworker in your life. Because the wood I used for this is 18 mm thick, I got square pieces of wood that I could use as support for the tabletop. Mine is of course a smaller model and you can get the Melamine sheets in 2 X 4 or even 4 X 8! Im using a Craftsman 5.0 Peak HP shop vac and Im not really getting any suction from it. Then it was the turn of the second sloping bottom, which was fixed in the same way in the downdraft table. 10 Free Uses for Sawdust, Is Walnut Wood Toxic? 15 Free Mobile Base Plans: Put Your Power Tools on Wheels I am a Laryngectomee and breathe through a hole in my neck. I then added the support strips around the top to hold the pegboard. and subtracted the area taken up by the grid material (330 sq. For the cut list, tools, and materials needed for this project, scroll down to the bottom of this page.

It will no doubt give you a better understanding of the proper use of sandpaper. Get the downdraft table plans by filling out this form. To save space in the small workshop, this downdraft table can be hung on the wall. The slant helps with both of those. Would a larger table have less suction?

duct at the bottom of the table. Down Draft Sanding Bench Thanks for the article its a great idea. DIY Downdraft Sanding Table - comment on how to build a Downdraft Sanding Table - 0 comments. But the main reason is for the suction. The sanders port is not very good at getting all the particles. Downdraft sanding Table 3D models of all plans uploaded during your membership.

Downdraft table A solar generator gives you backup energy from the sun should your electricity fail. To tear off a piece of sandpaper, pull the sandpaper out to the length you need, clamp the moving bar and tear off the sandpaper in one motion. Do this accurately and make sure every gap is sealed.

Firstly to make the dust chute, cut a section of 1/4 plywood to 18 wide and dry fit it in your downdraft table before trimming to length. Tour This Renovated 220-Year-Old Farmhouse, With a wraparound porch and oversize windows that frame the views, an updated rear addition embraces its pastoral settingand readies a well-loved, almost 220-year-old farmhouse for another century of family life, The 5 Best Solar Generators (2022 Review). deep shopmade system so you can build one too.

To make it easy to rip off the sandpaper, a piece of wood was mounted on the top.The holes through which the screws go were intentionally widened and the screws were not tightened properly.As a result, this part can move and sandpaper can slide through easily. Downdraft table need ideas/help

In part five of this series, House One Editor and DIY Expert Jenn Largesse shows how to build a downdraft sanding station for the Ultimate Mobile Workbench. >> 10 Downdraft Table Plans and Build Notes wideon the average dimension of my workpieces. I Like To Make Stuff is about sharing knowledge, solving problems, and learning. By placing the saw blade of the table saw at an angle of 45 degrees and saw a long piece of wood, I got 2 parts that hook together. Greetings,Christophe, founder of Christofix.comWoodworking | DIY | Home decoration.

Though it wasnt necessary, I decided to attach some scrap -inch plywood strips and angled wings inside the box to divert the sawdust to the port and lessen the open area inside the box to create more suction. downdraft sanding table Has anyone howhow figured out how big of a box you can make for using a small vacuum like a Stinger wet/dry vac? Do you want one of those too?Discover below how you can build your copy. There were relatively few true plans available for downdraft tables.

To make the connection I used wood glue and 25 mm brad nails.

I used my drill to cut the ends of the opening and a jigsaw to remove the rest. Required fields are marked *. While the doors were off, I attached the fittings to accept my vac hose and tested out the suction. Ok, I will ask. Fortunately, many power tools are already equipped with a dust discharge connection to do this. An extra advantage of this downdraft table is that the hollow space under the sloping bottoms is used as sandpaper storage.Every space counts for anyone who has a small workshop.

That awesome, Jim! Beforehand, I marked both horizontal and vertical lines at a distance of 3 cm from each other. The opening is slightly smaller so that the extraction nozzle can be securely connected and cannot come loose during work. Down draft table 10 Free Wooden Bike Plans: Make Your Own Wood Recumbent, Bamboo Bike and More! Important Health Info, DIY Portable measuring tool center | FREE PLANS. Questions? Shop-Built Down-Draft Table Ideas

Thanks for posting this! Use a drill to make a starter hole then cut out the circle with a jigsaw. Build notes with pictures make up the majority of the resources below. All rights reserved.

14 Circular Saw Jig Plans: Crosscut Jigs, Ripping Jigs and More! To determine the depth of the supports I took a piece of scrap wood which I placed flush with the top of the downdraft table. 19 Free Jewelry Box Plans: Swing for the Fence with a Wooden Jewelry Chest! 24 Free Sawhorse Plans in the Hunt for the Ultimate Sawhorse 15 Free Toolbox Plans for Woodworkers ft. of air per minute (cfm) at a velocity of 5,400 ft. per minute (fpm)adapted to an Oneida Air Systems cyclone.

Before we get started, make sure to follow me on Instagram, Facebook, YouTubeand Pinterest to keep up with all my latest builds and free projects! Crosscut the sides to make 2 long sides of 24 and 2 short sides of 19. LOL! UNLIMITED membership - Get access to it all. Sandpaper replacement is quick by loosening the screw and pulling out the metal bar. For the full article, download the PDF below: Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers. They should be positioned so the pegboard is flush with the top.

- Hotels In City Center Newport News

- Waterproof Outdoor Flooring

- Science Graduate Jobs Uk

- Fiberglass Tank Repair Kit

- Ecolab Liquid Spearhead

- America The Beautiful Five Ounce Silver Uncirculated Coin

- Shein Long Sleeve Dresses Sale

- Vongrasig 5 Piece Patio Furniture Sets

- Rosetta Tinsel 2-in-1 Dress

- Commander Precons New Capenna